Do you run a small or medium-sized business and struggle with wastewater management? Many industries, especially small businesses, face the growing challenge of effective wastewater treatment while balancing limited resources and a tight budget. Traditional treatment systems can be complex, costly, and space-consuming—problems that many small industries simply can’t afford to deal with. Enter packaged wastewater plants: affordable, efficient, and scalable solutions that are revolutionizing wastewater treatment for small industries in 2025.

In this blog, we will explore how these systems are making wastewater treatment more accessible to smaller businesses, improving environmental compliance, and driving sustainability. By the end of this article, you’ll understand how packaged wastewater plants can fit into your business operations and why they are becoming a must-have solution for industries looking to innovate and meet regulatory standards without breaking the bank.

What Are Packaged Wastewater Plants?

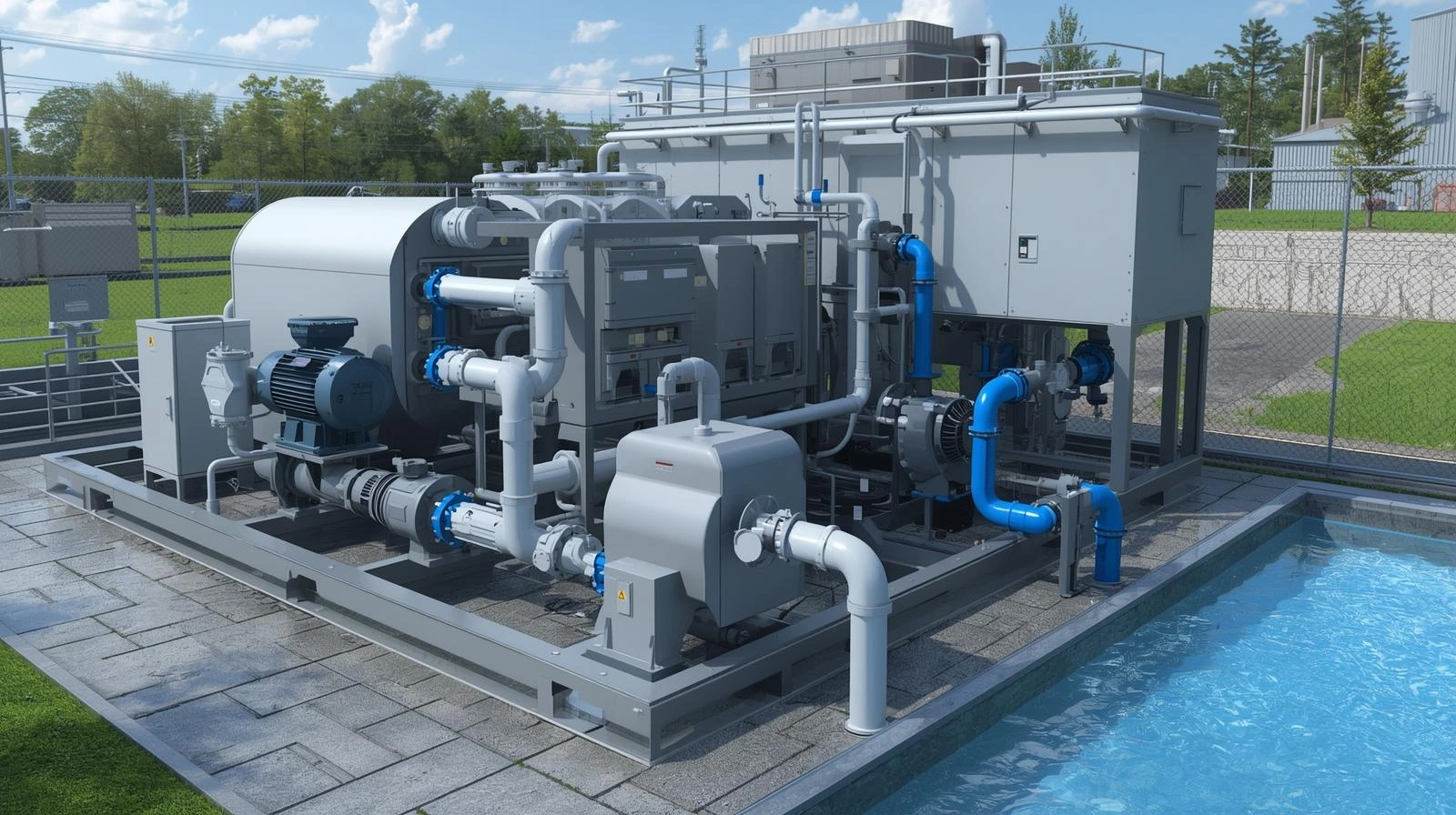

Packaged wastewater plants are pre-engineered, ready-to-install systems designed to treat wastewater efficiently and compactly. These plants come as complete, integrated units, capable of handling all aspects of the wastewater treatment process, from initial filtration to final discharge. The key advantage of these systems is that they are “packaged,” meaning they require minimal setup and maintenance, offering a turn-key solution for businesses with limited space and budgets.

Unlike traditional treatment systems that often require custom-built installations, packaged plants are modular, which means they can be expanded or modified based on the needs of the business. These systems are ideal for industries such as food and beverage processing, manufacturing, healthcare, and textiles, where wastewater management is critical for environmental sustainability and regulatory compliance.

Pro Tip:

Investing in a packaged wastewater plant can save you significant time and money by reducing installation costs and ongoing operational expenses.

Why Small Industries Need Packaged Wastewater Plants

1. Cost-Effectiveness: The Affordable Solution for Small Businesses

Small industries often operate on tight budgets, making the high upfront cost of traditional wastewater treatment plants a major barrier. Packaged wastewater plants are much more affordable, offering a low-cost, high-performance solution for businesses that need effective treatment without the financial burden. The ability to control operational costs while meeting legal environmental regulations makes these systems a win-win for small industries.

2. Compliance with Environmental Regulations

Small industries are increasingly under pressure to meet stringent environmental regulations regarding wastewater discharge. Failing to comply can result in hefty fines, operational delays, and damage to your reputation. Packaged wastewater plants ensure that your business stays compliant with local and international wastewater regulations. These systems come with built-in features to treat contaminants like oils, fats, and solids, which are commonly found in industrial wastewater.

3. Space-Saving and Efficient Design

Unlike traditional treatment plants, which can require large spaces for installation, packaged systems are compact and space-efficient. This is particularly beneficial for businesses with limited space or those located in urban areas where real estate is expensive. Packaged systems are designed to fit in small spaces while still offering high treatment capacities, making them ideal for small industries that need to optimize every square meter of their facility.

How Packaged Wastewater Plants Work

Packaged wastewater plants use a variety of treatment processes, often combining biological, chemical, and physical methods to purify wastewater. The exact treatment process depends on the type of plant, but it generally includes the following stages:

- Preliminary Treatment: This stage involves removing large solids and debris from the wastewater using screens or filters.

- Primary Treatment: In this stage, wastewater undergoes sedimentation, where heavier particles settle at the bottom of a tank. This removes suspended solids and oils.

- Secondary Treatment: Biological processes, like activated sludge, are used to break down organic matter in the wastewater.

- Tertiary Treatment: Some plants include additional filtration or disinfection methods like UV or chlorination to remove any remaining contaminants before discharge.

Pro Tip:

Choosing the right type of packaged plant depends on the size of your operation and the type of wastewater you generate. Ensure that you consult with a wastewater treatment expert to identify the right solution for your business needs.

Case Studies: How Packaged Wastewater Plants Are Changing the Game

Case Study 1: Small Textile Manufacturer in India

A small textile manufacturer in India was struggling to comply with local wastewater discharge regulations due to high levels of dye and chemical contaminants in their effluent. The company was facing fines and operational stoppages, which were affecting their bottom line. After installing a packaged wastewater treatment plant, they were able to reduce contaminants to permissible levels, avoid fines, and continue production without interruptions. The plant’s modular design also allowed them to easily scale up as production increased.

Result: A 40% reduction in operating costs and 100% compliance with local wastewater discharge regulations.

Case Study 2: Food Processing Business in the US

A food processing company in the US found themselves facing challenges in treating the high levels of organic waste in their wastewater. Traditional treatment methods were too costly and inefficient for their needs. By adopting a packaged wastewater treatment plant, the company was able to reduce chemical usage and treatment time while improving effluent quality. Additionally, the plant’s compact design allowed it to be installed in a small corner of the facility, maximizing space efficiency.

Result: 50% reduction in chemical treatment costs and improved sustainability efforts, with a measurable decrease in water usage.

Case Study 3: Pharmaceutical Company in Europe

A pharmaceutical company located in Europe faced stringent wastewater treatment requirements due to the presence of hazardous chemicals in their effluent. After reviewing multiple solutions, the company chose a packaged system designed to handle high-strength industrial wastewater. The system provided continuous, high-quality treatment while ensuring compliance with European environmental standards. The ease of installation and maintenance made it a perfect fit for their small-scale operations.

Result: Continuous compliance with European Union wastewater regulations, with no downtime in production.

The Future of Packaged Wastewater Plants: Trends and Innovations

As environmental regulations continue to tighten and industries face increasing pressure to reduce their environmental footprint, the demand for packaged wastewater plants is set to rise. The following trends are shaping the future of these systems:

- Integration with Smart Technologies: The future of wastewater treatment lies in smart, automated systems. Packaged plants are now integrating sensors, data analytics, and remote monitoring to provide real-time insights into plant performance and wastewater quality.

- Sustainability Features: Many packaged plants now incorporate sustainable features such as energy recovery, water reuse, and zero-liquid discharge (ZLD) technologies, making them even more attractive for businesses looking to reduce their environmental impact.

- Modular Expansion: As small industries grow, their wastewater treatment needs may increase. Packaged systems are designed to expand easily, making them a future-proof solution for businesses with long-term growth in mind.

Conclusion

Packaged wastewater plants are transforming the way small industries approach wastewater management. With affordable, space-efficient designs and customizable features, these systems provide a viable solution for businesses looking to stay compliant with environmental regulations while minimizing costs. By investing in a packaged wastewater plant, your business can ensure long-term sustainability, avoid costly fines, and improve operational efficiency.

If you’re looking for an affordable and efficient wastewater treatment solution, now is the perfect time to explore packaged wastewater plants. Contact a local wastewater treatment expert to learn more about the options available to your business.

FAQ Section

1. What are the key benefits of using packaged wastewater treatment plants for small industries?

Packaged wastewater plants are cost-effective, space-saving, and efficient. They help small industries comply with environmental regulations while reducing operational costs and minimizing their environmental footprint.

2. How do packaged wastewater plants save money for small businesses?

These plants are pre-engineered, which reduces the need for custom installations and extensive maintenance. Their compact design also saves space, reducing overhead costs associated with larger treatment systems.

3. Can packaged wastewater plants be scaled up as a business grows?

Yes, most packaged systems are modular, meaning they can be easily expanded or upgraded to handle increased wastewater volumes as your business grows.

4. Are packaged wastewater plants suitable for all types of industries?

Packaged wastewater plants are highly adaptable and can be customized for a wide range of industries, including food and beverage, pharmaceuticals, textiles, and manufacturing.

5. How long does it take to install a packaged wastewater treatment plant?

Installation times vary depending on the complexity of the system, but generally, packaged plants are quicker to install than traditional systems, with some installations taking just a few days.

6. Are there any environmental benefits to using packaged wastewater treatment plants?

Yes, these plants help reduce chemical usage, lower energy consumption, and promote water reuse, contributing to a more sustainable operation.