Pharmaceutical effluent treatment: case study

Pharmaceutical effluent

“Pharmaceutical effluent” refers to the liquid waste or discharge produced during the manufacturing processes in the pharmaceutical industry. This effluent can contain various substances, including chemicals, drugs, and other contaminants used in the production of pharmaceuticals.

Pharmaceutical effluent treatment

“Pharmaceutical effluent treatment” specifically refers to the processes and technologies implemented to treat and manage the pharmaceutical effluent before it is discharged into the environment. The treatment aims to remove or reduce the concentration of harmful substances and contaminants present in the effluent, ensuring that the discharged water meets regulatory standards and does not pose environmental risks.

In short, “Pharmaceutical effluent” is the wastewater generated from pharmaceutical manufacturing, while “Pharmaceutical effluent treatment” involves the methods employed to treat and mitigate the environmental impact of this wastewater before it is released.

Pharmaceutical effluent treatment case study

Water is a critical raw material for pharmaceutical manufacturing processes, water treatment and reuse has been the utmost concern of the industry to ensure consistent and quality supply of water for various operations. In the recent years effluents are discharged directly into the sewage and water bodies without treatment. This has resulted in not only higher concentrations of drugs and antibiotics in effluent, groundwater, irrigated soil and plants but also the detection of antibiotic resistant genes in the receiving environment of the pharmaceutical effluent.

The present project was executed by Water Care Services Pakistan to demonstrate one of the wastewater treatment systems (BioCleaner) which is a form of green technology based on biological treatment for the efficient removal of harsh chemicals and allied contaminants from an effluent stream of a pharmaceutical plant located in Lahore.

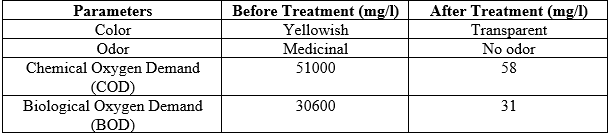

Results showed remarkable reduction in BOD and COD parameters of treated effluent up to 99.8%. This indicated removal of toxic pharmaceutical compounds (PCs) and active pharmaceutical agents (APIs) from the effluent water with great efficiency which are otherwise detrimental for the environment and pose risk of ecotoxicity. Treated water also showed no odor, no sludge and no chemical addition. The discharge of treated effluent in the surrounding environment not only decreased the occurrence of pollution of receiving water bodies but also improved the aquatic environment where fish & turtles species are surviving due to increased levels of DO. In addition to this, the treated water is also used for gardening and agriculture purposes as well.

In the pharmaceutical industry, sustainability is evident through initiatives like pharmaceutical effluent treatment for responsible wastewater disposal. Industries also prioritize air quality monitoring to minimize their carbon footprint and uphold environmental standards. Moreover, soil quality monitoring ensures the overall health of ecosystems, reflecting a holistic commitment to environmental protection.