Bottled Water Plant

PSQCA Definition of Bottled Drinking Water

According to the Pakistan Standards and Quality Control Authority (PSQCA), bottled drinking water refers to water that is not classified as natural mineral water, and is packaged in hermetically sealed containers or bottles of various materials, shapes, and sizes. These containers are specifically designed to be safe and suitable for direct human consumption.

Bottled drinking water is officially categorized as a food product, subject to relevant safety and quality regulations.

Salient Features

WCSP Bottled Water Plants – Quality, Efficiency & Compliance

Water Care Services Pakistan (WCSP) proudly manufactures bottled water plants that fully comply with recognized bottled water standards, ensuring safety, taste, and reliability throughout the production process.

Key features of these plants include:

Compact, Standard-Compliant Design – Space-efficient systems built to meet industry regulations

High Operational Efficiency – Engineered for maximum productivity with minimal resource consumption

Fully Automatic Functionality – Streamlined automation for seamless operation and reduced manual handling

Pleasant Taste & Long Shelf Life – Delivers superior water quality and product longevity

Durable Fabricated Materials – Components selected for extended service life and consistent performance

Complete Documentation Package – Includes all essential technical and compliance support documents

Time-Saving Configuration – Optimized setup for fast processing and minimal downtime

Definition of a Bottled Water Plant

Bottled Water Plants – Ensuring Access to Safe Hydration

A bottled water plant is a specialized facility focused on the sourcing, purification, and packaging of water for direct consumer use. In response to the growing global demand for clean drinking water, these plants play a pivotal role in delivering safe, regulated, and ready-to-consume hydration solutions.

By implementing rigorous quality standards and advanced treatment processes, bottled water facilities stand at the forefront of public health, ensuring reliable access to purified water across diverse markets.

Growing Demand for Bottled Water

🌍 Rising Global Demand for Bottled Water

In recent years, the global consumption of bottled water has witnessed a significant surge—fueled by shifting lifestyle patterns, growing awareness of health and wellness, and an increasing preference for convenient, on-the-go hydration.

This upward trend reflects a broader movement toward accessible and health-conscious beverage options, positioning bottled water as an essential product in both domestic and commercial markets.

Addressing Consumer Preferences

🥤 Convenience at the Core of Bottled Water Appeal

Bottled water plants are designed to meet the growing demand for portable and hassle-free hydration, aligning perfectly with the preferences of today’s on-the-go consumers. The simplicity of grabbing a bottle and staying refreshed—anytime, anywhere—has evolved into a defining lifestyle choice across diverse demographics.

Role in Ensuring Water Quality

✅ Quality Assurance & Accessibility in Bottled Water Production

Quality assurance stands at the heart of every bottled water plant. These facilities follow strict purification protocols and maintain rigorous quality control measures to ensure that every bottle meets the highest industry safety and hygiene standards.

Operating a bottled water plant offers clear advantages in responding to the growing need for clean and safe hydration. By utilizing advanced Water Testing Kits, producers can continually verify water purity, while connected Water Shops enhance public accessibility—making it easier for consumers to obtain premium bottled water.

This integrated approach reflects the industry’s unwavering commitment to delivering safe, dependable, and high-quality drinking water to communities.

Addressing Water Contamination Issues

🚰 Bottled Water Plants – A Response to Rising Contamination Concerns

The rapid expansion of bottled water plants stems largely from escalating concerns over water contamination. As pollutants and toxins continue to infiltrate natural water sources, conventional treatment methods often fall short in addressing the full spectrum of impurities.

To meet this challenge, bottled water facilities deploy advanced filtration and purification technologies, ensuring that every drop meets strict safety and quality standards. These plants serve as a dependable source of clean and safe drinking water, reinforcing consumer trust and promoting public health.

Catering to High Demand for Clean Drinking Water

💧 Meeting the Soaring Demand for Clean Drinking Water

The global need for clean and safe drinking water is at an all-time high, propelled by factors such as rapid population growth, urban expansion, and the escalating effects of environmental degradation. In many regions, limited access to clean tap water compels individuals to seek bottled water as a reliable and health-conscious alternative.

Bottled water plants play a vital role in addressing this challenge by producing large volumes of purified water, ensuring consistent supply and nationwide distribution to communities in need.

Benefits of Bottled Water Plants

✅ Upholding Quality Standards & Expanding Access to Safe Drinking Water

Ensuring Regulatory Compliance A major advantage of bottled water plants lies in their commitment to strict quality assurance protocols. Each batch of water undergoes comprehensive testing to confirm compliance with regulatory requirements for purity and safety. This meticulous approach provides consumers with confidence and peace of mind, knowing they’re drinking clean, high-quality water.

Providing Reliable Access to Clean Water Bottled water plants also serve as a convenient and dependable solution for accessing safe drinking water—particularly in areas with limited tap water infrastructure. Their products are easy to transport and store, making them ideal for households, commercial establishments, and emergency relief efforts. With these plants in operation, safe hydration is always within reach, no matter the circumstance.

Ensuring Water Quality and Safety

🛡️ Quality Assurance & Hygiene Protocols at Water Care Services Pakistan

Robust Quality Control Practices At Water Care Services Pakistan (WCSP), a comprehensive set of quality control measures is implemented across every phase of production—from water sourcing to final bottling. Each stage is rigorously monitored and tested to identify and eliminate potential contaminants or impurities, ensuring the water consistently adheres to the highest purity and safety standards.

Stringent Hygiene Standards In parallel with quality control, WCSP enforces strict hygiene protocols to safeguard product integrity. Bottling machinery is regularly cleaned and sanitized to prevent bacterial growth, while personnel receive specialized hygiene training to maintain cleanliness and operational discipline.

Through this unwavering dedication to safety and sanitation, WCSP guarantees that every bottle delivered to customers is safe, reliable, and ready for consumption.

Environmental Considerations

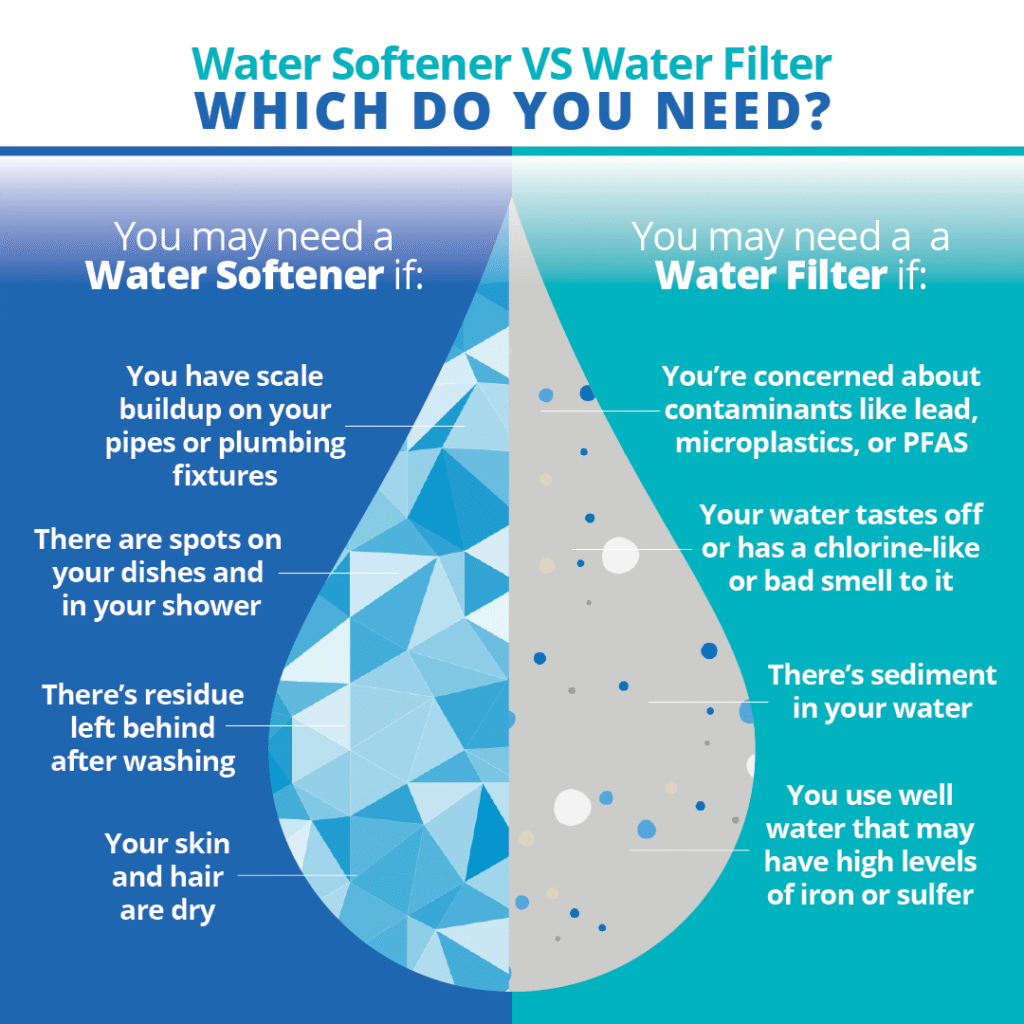

⚙️ Custom-Built Water Softeners for Every Scale

We design and manufacture water softening systems ranging from 100 LPH (laboratory scale) to 200 m³/hr (industrial scale), tailored to meet diverse application needs.

Why Water Softening Matters

Hard water can lead to clogged pipes, reduced soap efficiency, and long-term damage to plumbing and equipment. Our water softeners help eliminate these issues by removing calcium and magnesium ions—delivering numerous benefits:

Protects Infrastructure: Prevents scale buildup in pipelines, extending their lifespan

Reduces Energy Costs: Lowers domestic water heating expenses by 15–20%

Extends Equipment Life: Enhances the performance and durability of household and industrial appliances

Improves System Efficiency: Supports optimal operation of solar heaters, HVAC systems, and water-based industrial processes

Health & Wellness Benefits of Softened Water

Integrated Water Treatment for Quality & Safety

Enhance your water quality with a comprehensive solution that combines:

Water Softening Plants – For reduced hardness and scale prevention

Chlorination Systems – For reliable and effective disinfection

Ozone Generators – For eco-friendly, chemical-free purification

Sustainable Living with Eco-Friendly Water Softening

Incorporating environmentally friendly water softening systems into your home allows you to enjoy the benefits of luxuriously softened water while actively supporting water conservation efforts. This responsible choice helps protect our planet’s valuable water resources and promotes a more sustainable future for generations to come.

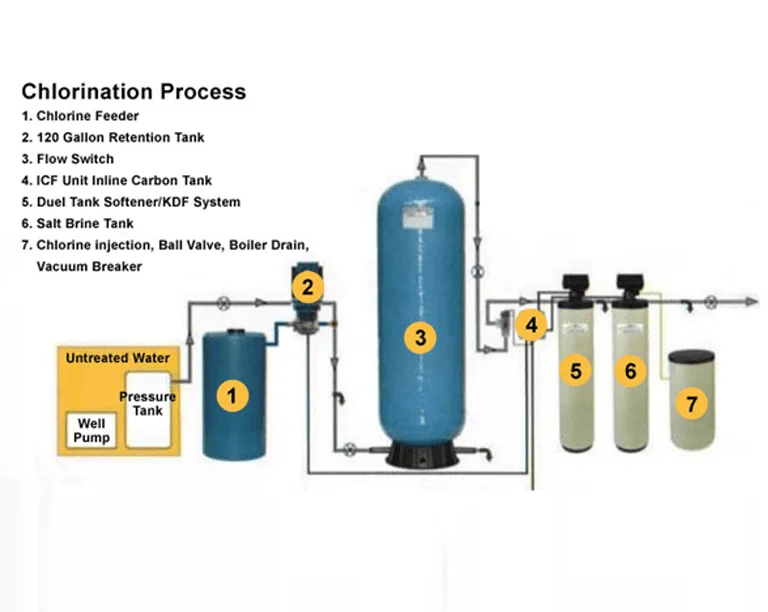

Chlorination Systems – Reliable Disinfection at Low Cost

Chlorine-based systems are a proven and cost-effective solution for eliminating bacteria and viruses from water sources, making them a widely adopted method for water disinfection.

At Water Care Services Pakistan (WCSP), our standard chlorination setup includes a chemical dosing pump that accurately injects diluted chlorine into the incoming water stream. The treated water is then held in a contact tank, allowing sufficient time for disinfection. These tanks come in various capacities, and a minimum contact time of 20 minutes is required for optimal effectiveness. After disinfection, any excess chlorine is removed to preserve the water’s taste and odor.

Key Features

Effectively eliminates harmful bacteria, including coliforms and E. coli

Removes unpleasant hydrogen sulfide (sulfur) odors

Oxidizes iron and manganese, making them easier to filter

Economical and efficient solution for water treatment

Gas Chlorination

Gas chlorination introduces chlorine gas directly into the water, offering a highly efficient solution for large-scale disinfection. It is a preferred method in municipal water treatment plants due to its effectiveness and scalability.

Liquid Chlorination

This method uses liquid chlorine solutions to disinfect water, allowing for precise dosage control. Liquid chlorination is widely adopted in industrial and commercial applications for its flexibility and reliability.

Tablet Chlorination

Tablet chlorination involves the use of slow-dissolving chlorine tablets, which release chlorine gradually into the water. It is ideal for small-scale systems, such as residential water treatment units and swimming pools, where ease of use and low maintenance are key.

Importance of Chlorination in Water Treatment

As a critical step in the water purification process, chlorination plays a key role in safeguarding public health by preventing waterborne diseases. Its broad-spectrum reactivity with various contaminants makes chlorine a highly versatile and dependable disinfectant across residential, industrial, and municipal applications.

Advantages of Chlorination in Water

Chlorination is a widely trusted method for water disinfection due to its proven ability to eliminate harmful pathogens, including bacteria and viruses. Its consistent performance in protecting public health has made it a cornerstone of modern water treatment. Moreover, its adaptability across a range of applications—from municipal systems to industrial processes—underscores its reliability and versatility.

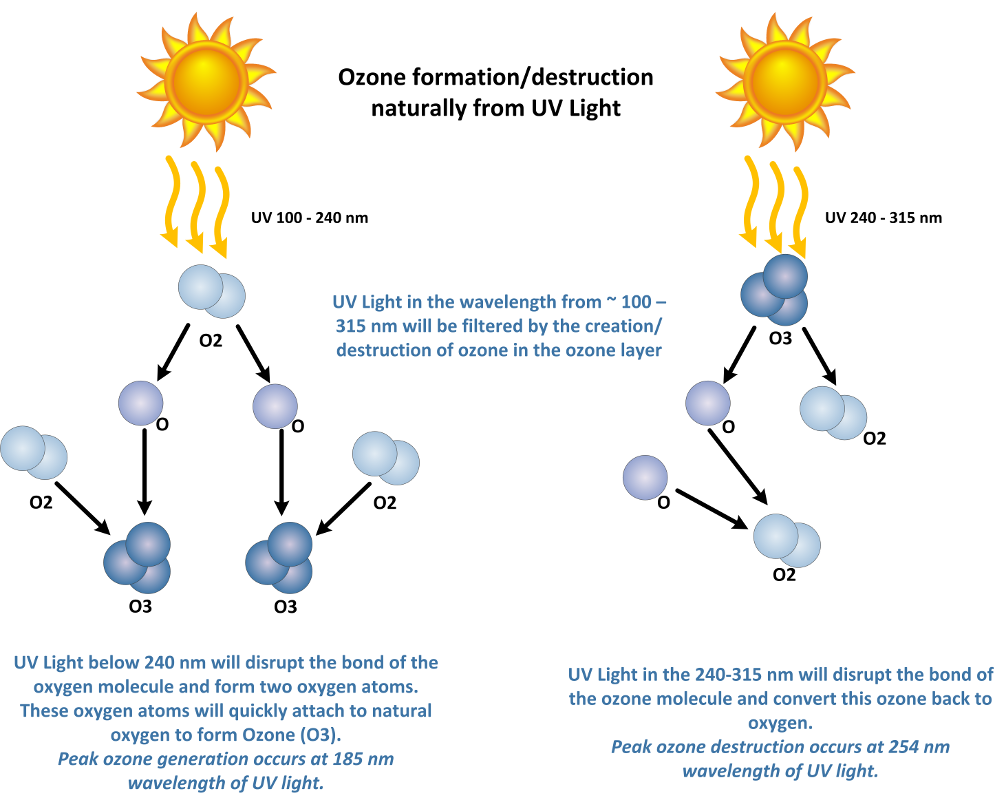

Ozone Disinfection – A Century of Innovation

Due to its unstable nature—rapidly converting back to oxygen—ozone must be generated on-site using an ozone generator, ensuring maximum effectiveness at the point of use.

Ozone Generators – Advanced Disinfection for Water Treatment

Ozone generators are primarily used for the disinfection of water, targeting and destroying microorganisms responsible for infectious diseases. This process ensures a high level of microbial safety without the use of chemical residues.

How Ozone is Produced

Ozone is most commonly generated through the corona discharge method, where a controlled electrical spark is passed across an air gap containing a feed gas—either dry air or oxygen-enriched air.

The feed gas is dried to a dew point of –60°F to prevent the formation of nitric acid, which can corrode the generator.

In the presence of moisture, nitric oxide produced during the discharge can react to form corrosive byproducts.

Why Ozone?

Ozone attacks bacterial cells by penetrating and rupturing their cell walls.

Repeated ozone collisions cause the cell to lose structure and eventually collapse.

The required contact time is only 1 to 6 minutes, and ozone has a half-life of 22 minutes in water.

Integrated Ozone Solutions for Modern Water Systems

Leverage the natural disinfection power of ozone by integrating it with systems like automated filling machines and Water Dispenser ATMs. This ensures a sterile, contaminant-free environment for efficient and hygienic water packaging and dispensing—raising the bar for production quality and safety.

Integrated Ozone Solutions for Modern Water Systems

Leverage the natural disinfection power of ozone by integrating it with systems like automated filling machines and Water Dispenser ATMs. This ensures a sterile, contaminant-free environment for efficient and hygienic water packaging and dispensing—raising the bar for production quality and safety.

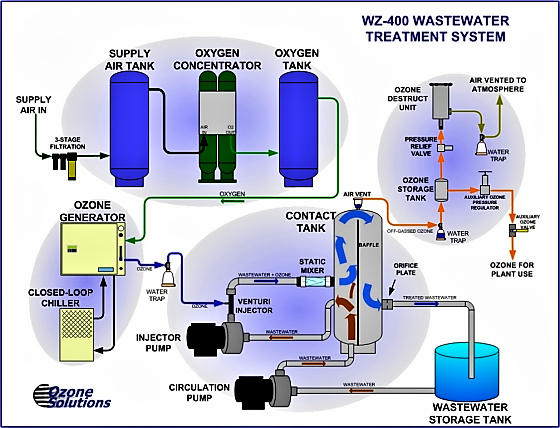

Key Components of an Ozone Generation System

Feed Gas Preparation

- The feed gas used in ozone generation can be either dry air or concentrated oxygen:

- Dry Air: Air that has been dehumidified to a dew point of –60°F or lower

- Concentrated Oxygen: Oxygen with a purity of 90% or higher, with moisture removed for optimal ozone production.

Power Input

The primary energy consumption occurs during the conversion of oxygen into ozone. Additional power is required for:

- Feed gas preparation

- Ozone transfer and contact processes

- Operation of control systems, instrumentation, and monitoring equipment

Ozone Generation Unit

- Ozone is generated on-site using the corona discharge method, which involves applying high voltage between closely spaced electrodes. The feed gas—either dry air or concentrated oxygen—is passed through this high-energy field, causing oxygen molecules (O₂) to split and recombine into ozone (O₃).

- With dry air: Ozone concentration ranges from 1–3% by weight

- With pure oxygen: Ozone concentration increases to 3–10% by weight

Contact Basin – Ozone Transfer to Water

Efficient mixing of ozone with water is critical for effective disinfection. Two primary methods are used:

Bubble Diffusion: Ozone is introduced into water through fine-pore diffusers, forming small bubbles. As these bubbles rise, ozone diffuses into the surrounding water, achieving disinfection.

Venturi Injection: Water is forced through a venturi injector, creating a pressure differential that generates a vacuum. This vacuum draws ozone into the water stream through a suction port, ensuring rapid and efficient mixing.

Concentrated oxygen refers to a purified gas containing a minimum of 90% oxygen, with all moisture thoroughly eliminated to ensure optimal performance in specialized applications.

Filling Machine Technologies

Filling machines function based on various operational principles—including gravity, piston, vacuum, and volumetric filling methods. Each technology is strategically designed to suit the unique characteristics of specific products and container formats, offering manufacturers highly adaptable and efficient packaging solutions.

Benefits of Integrating Filling Machines into Production

Incorporating filling machines into manufacturing operations offers a wide array of advantages. These automated systems streamline bottle and container filling, reducing reliance on manual labor and significantly boosting production efficiency.

Moreover, their precise dispensing capabilities help minimize product wastage and spillage, ensuring accurate fill volumes for each container—leading to reduced material costs and improved overall profitability.

Versatility of Filling Machines Across Industries

A major strength of filling machines lies in their remarkable adaptability, enabling seamless integration across diverse sectors such as food and beverage, pharmaceuticals, cosmetics, chemicals, and more. Their flexible design supports a wide variety of product consistencies, container sizes, and shapes, making them an ideal solution for complex and multi-format packaging requirements.

Material Compatibility & Scalability

Filling machines are engineered to operate efficiently with a wide variety of packaging materials—including glass, plastic, metal, and flexible formats such as pouches and sachets. This remarkable flexibility enables seamless integration into both small-scale setups and high-capacity production lines, making them a reliable solution for diverse manufacturing needs.

⚙️ Driving Productivity with Filling Machines

One of the key benefits of filling machines is their substantial impact on production efficiency. By automating the filling operation, reducing manual errors, and ensuring precise and uniform fill levels, these systems not only streamline workflow but also uphold consistent product quality throughout the manufacturing process.

⚙️ Enhancing Production Efficiency with Filling Machines

Filling machines play a pivotal role in optimizing manufacturing performance. Through automated dispensing, they minimize human error and deliver consistently accurate fill volumes. This results in improved workflow efficiency and ensures uniform product quality throughout the production cycle.

Smart Design for Hassle-Free Maintenance

Modern filling machines are built with maintenance efficiency in mind, incorporating quick-change components and intuitive interfaces that simplify cleaning and servicing tasks. This streamlined design reduces production interruptions, enabling faster upkeep and maximizing operational uptime.

Built-In Safety for Reliable Operation

Safety is a top design priority in these machines. They feature integrated protection systems such as overfill prevention, emergency stop functions, and full compliance with industry safety standards—ensuring the well-being of operators while maintaining product integrity throughout the production process.

Evolving to Meet Modern Manufacturing Demands

The ongoing advancement of filling machine technology reflects their remarkable flexibility in meeting evolving production requirements. Manufacturers place a strong emphasis on intuitive user interfaces and integrate cutting-edge innovations to simplify operations and improve overall user experience.

Automated Precision for High-Speed Filling

A key advantage of modern filling machines is their advanced automation capability. With a single command, these systems can efficiently and accurately fill hundreds to thousands of containers per hour, significantly accelerating production workflows.

This high-speed automation not only reduces operational time and labor requirements but also maintains consistent fill levels and packaging reliability, ensuring superior quality and repeatability across large-scale operations.

Precision Engineering for Optimal Filling

Filling machines are engineered for exceptional accuracy, ensuring that each container receives the precise volume of product required. This eliminates the risk of overfilling or underfilling, effectively reducing wastage and spillage to negligible levels. By minimizing material loss, these systems play a vital role in achieving cost-efficiency and enhancing profitability across production lines.

Unmatched Accuracy with Advanced Filling Technology

Modern filling machines integrate cutting-edge technology and high-precision calibration systems to deliver consistently accurate fill volumes. From tiny medication vials to large beverage containers, these machines ensure exact product dispensing tailored to the specific packaging format.

This exceptional level of precision not only maintains product quality and consistency but also reinforces consumer confidence and brand reliability—making it a vital asset across regulated and high-demand industries.

Maintenance Essentials for Filling Machines

Though filling machines are known for their durability and reliability, routine maintenance is vital to ensure long-term efficiency and operational excellence. Proper upkeep not only extends equipment lifespan but also maintains consistent performance.

Regular Cleaning & Sanitization

Implementing thorough cleaning and sanitization protocols is critical for maintaining hygiene and preventing contamination.

Routine cleaning helps eliminate product residue

Prevents microbial buildup

Ensures the system functions at peak capacity with minimal disruptions

Adaptable Filling Solutions for Varied Packaging Needs

A standout benefit of filling machines is their exceptional versatility in handling containers of various sizes and shapes—ranging from standard bottles and jars to tubes and flexible pouches. With customizable configurations, these machines accommodate a wide spectrum of packaging formats, empowering manufacturers to streamline operations and quickly respond to evolving market demands with confidence and efficiency.

Innovation-Driven Performance in Filling Technology

Ongoing advancements in filling machine design continue to redefine standards of speed and precision. With the integration of enhanced dosing systems and accelerated filling cycles, today’s machines empower manufacturers to reach new heights in production accuracy, efficiency, and throughput—ensuring seamless alignment with modern manufacturing demands.

Advancing Sustainability Through Intelligent Packaging

The rising focus on sustainable packaging is driving innovation across the industry. Modern filling machines are now engineered to operate efficiently with environmentally friendly materials, including biodegradable plastics and recyclable containers.

By supporting eco-conscious packaging throughout the production cycle, these machines contribute significantly to reducing environmental impact and fostering a greener, more responsible future within the manufacturing landscape.

Final Thoughts – Essential Role in Modern Manufacturing

Filling machines serve as cornerstone technologies in today’s manufacturing landscape, delivering precise, efficient, and scalable packaging solutions across a wide spectrum of industries. Their flexibility, productivity, and integrated safety features make them indispensable in advancing modern production workflows.

To further elevate beverage service efficiency, integrate Filling Machines, Automatic Water Dispensers, and Juice & Beverage Systems—ensuring streamlined operations, minimal waste, and heightened customer satisfaction across service environments.

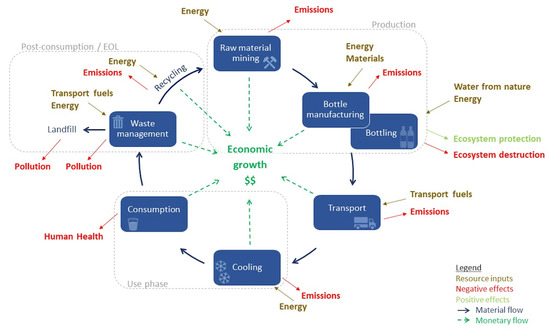

Sustainable Wastewater Management in the Beverage Industry

The effective treatment of wastewater generated by the beverage industry is vital for fostering environmental stewardship and advancing sustainable industrial practices. As global beverage consumption continues to rise, so does the volume of wastewater—typically comprising a complex blend of organic compounds (e.g., sugars) and inorganic substances (e.g., chemicals and process byproducts).

Robust management and treatment strategies are essential to prevent environmental degradation, conserve water resources, and comply with regulatory standards. Beyond safeguarding natural ecosystems and maintaining water quality, innovative approaches to wastewater treatment also address pressing challenges such as water scarcity and industrial pollution.

To promote long-term sustainability, the industry must prioritize the exploration and implementation of advanced, efficient treatment technologies—reinforcing its commitment to responsible environmental practices and resilient production systems.

Biological Treatment for Beverage Industry Wastewater

Effluent from soft drink manufacturing facilities typically contains a wide array of pollutants, including suspended solids, organic matter, elevated pH levels, chemical oxygen demand (COD), biochemical oxygen demand (BOD), as well as nitrates, phosphates, sodium, and potassium.

To address these complex contaminants, Water Care Services Pakistan implemented a targeted project showcasing the performance of the Bio Cleaner wastewater treatment system. Leveraging environmentally friendly biological treatment technology, Bio Cleaner was deployed at a beverage production facility in Lahore to effectively eliminate harsh chemicals and associated impurities—demonstrating its capability to support sustainable effluent management in industrial operations.

Bio Cleaner – Sustainable & Economical Wastewater Treatment

Bio Cleaner presents an innovative, cost-effective, and eco-friendly solution for addressing wastewater challenges across global communities. This biologically driven technology eliminates the need for additional chemicals or enzymes, offering low operational costs with zero sludge production and odor-free performance.

A successful deployment at a beverage industry effluent treatment facility demonstrated the system’s effectiveness in removing contaminants, reinforcing its role as a sustainable alternative in modern wastewater management.

BioCleaner Technology – Proven Efficiency in Wastewater Treatment

BioCleaner microbes have demonstrated a strong capacity to reduce pollutant levels to within the limits prescribed by the National Environmental Quality Standards (NEQS). Performance results revealed significant reductions in key indicators including Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Dissolved Solids (TDS), oil and grease content, along with notable decreases in heavy metals and total toxic substances.

This compelling performance reinforces BioCleaner as a critical solution in achieving effective wastewater treatment, aligning both with environmental compliance and sustainable effluent management goals.

Championing Sustainability in Beverage Industry Wastewater Treatment

Sustainable management of wastewater in the beverage industry is critical for environmental protection and regulatory adherence. Leveraging innovative solutions like the Bio Cleaner wastewater treatment system offers a powerful approach to mitigating industrial discharge impacts.

By integrating such eco-friendly technologies, the industry fosters responsible operational practices that drive progress toward a more sustainable future. These advancements not only safeguard ecosystems and help preserve valuable water resources, but also effectively address urgent concerns like water pollution and scarcity—reinforcing the industry’s commitment to environmental resilience.

Importance of Quality Setup in Juice & Beverage Production

A refreshing taste, paired with visually appealing packaging and an extended shelf life, are key attributes of successful juice and beverage products. Among the essential components, high-quality water plays a pivotal role in ensuring product integrity and flavor consistency.

Understanding this critical requirement, Water Care Services Pakistan (WCSP) has delivered best-in-class water treatment setups tailored specifically for beverage production. Their advanced solutions help manufacturers maintain hygienic standards, preserve taste profiles, and support efficient processing workflows.

Establishing a robust Juice & Beverage Setup is fundamental for achieving excellence in both product quality and operational performance.

Key Highlights of Beverage Processing Excellence

Robust Product Formulation: Developed with a strong and stable formulation to ensure consistency and performance.

Extended Shelf Life: Engineered to maintain freshness and quality over a prolonged period.

Codex-Compliant Processing: Adheres strictly to international Codex Alimentarius standards for food safety and production integrity.

Premium Water Quality: Utilizes high-grade water as a primary ingredient to uphold purity and taste.

Efficient Machinery Performance: Supported by advanced equipment, ensuring seamless processing and reliable output.

Welcome to Your Juice & Beverage Setup

At the heart of every exceptional beverage lies one essential ingredient: pure, high-quality water. As leaders in water treatment solutions, we’re committed to ensuring that every drop used in your juice and beverage setup is crystal-clear, safe, and optimized for taste.

Our expertise extends beyond basic treatment—we deliver water that not only complies with stringent regulatory standards, but also elevates flavor profiles and enhances the safety and consistency of your products.

Customized Water Treatment for Every Beverage

At Juice & Beverage Setup, we understand that each beverage has its own distinct water quality requirements. That’s why our tailored water treatment solutions are specifically engineered to serve the diverse needs of juice bars, cafés, and beverage creators alike.

Prioritizing Health with Premium Water Treatment

Your health is our foremost concern. That’s why our water treatment solutions strictly follow the highest industry standards, ensuring every drop used in your beverage setup is pure, contaminant-free, and safe for consumption.

With our commitment to quality and safety, you can confidently serve beverages that are not only refreshing and flavorful, but also uphold the well-being of every customer.

Committed to Quality & Environmental Sustainability

In addition to delivering exceptional quality, we proudly advocate for eco-conscious practices. Our environmentally friendly water treatment methods are designed to minimize the ecological footprint of your beverage production process.

Together, let’s craft drinks that not only delight the senses, but also support a greener, healthier future—where sustainability and refreshment go hand in hand.

Elevate Beverage Innovation with Advanced Water Solutions

Step into a new era of beverage excellence with our cutting-edge water treatment technologies—designed to unlock and preserve the natural flavors of your ingredients. Whether you’re crafting juices or specialty drinks, our systems ensure every sip delights your customers and leaves them wanting more.

To further refine your beverage production strategy, consider integrating Bottled Water Plant technology alongside Water Testing Kits for optimal quality control, consistency, and consumer satisfaction.

PSQCA Definition of Bottled Drinking Water

According to the Pakistan Standards and Quality Control Authority (PSQCA), bottled drinking water refers to water that is not classified as natural mineral water, and is packaged in hermetically sealed containers or bottles of various materials, shapes, and sizes. These containers are specifically designed to be safe and suitable for direct human consumption.

Bottled drinking water is officially categorized as a food product, subject to relevant safety and quality regulations.

WCSP Bottled Water Plants – Quality, Efficiency & Compliance

Water Care Services Pakistan (WCSP) proudly manufactures bottled water plants that fully comply with recognized bottled water standards, ensuring safety, taste, and reliability throughout the production process.

Key features of these plants include:

Compact, Standard-Compliant Design – Space-efficient systems built to meet industry regulations

High Operational Efficiency – Engineered for maximum productivity with minimal resource consumption

Fully Automatic Functionality – Streamlined automation for seamless operation and reduced manual handling

Pleasant Taste & Long Shelf Life – Delivers superior water quality and product longevity

Durable Fabricated Materials – Components selected for extended service life and consistent performance

Complete Documentation Package – Includes all essential technical and compliance support documents

Time-Saving Configuration – Optimized setup for fast processing and minimal downtime.

Bottled Water Plants – Ensuring Access to Safe Hydration

A bottled water plant is a specialized facility focused on the sourcing, purification, and packaging of water for direct consumer use. In response to the growing global demand for clean drinking water, these plants play a pivotal role in delivering safe, regulated, and ready-to-consume hydration solutions.

By implementing rigorous quality standards and advanced treatment processes, bottled water facilities stand at the forefront of public health, ensuring reliable access to purified water across diverse markets.

Rising Global Demand for Bottled Water

In recent years, the global consumption of bottled water has witnessed a significant surge—fueled by shifting lifestyle patterns, growing awareness of health and wellness, and an increasing preference for convenient, on-the-go hydration.

This upward trend reflects a broader movement toward accessible and health-conscious beverage options, positioning bottled water as an essential product in both domestic and commercial markets.

Convenience at the Core of Bottled Water Appeal

Bottled water plants are designed to meet the growing demand for portable and hassle-free hydration, aligning perfectly with the preferences of today’s on-the-go consumers. The simplicity of grabbing a bottle and staying refreshed—anytime, anywhere—has evolved into a defining lifestyle choice across diverse demographics.

Quality Assurance & Accessibility in Bottled Water Production

Quality assurance stands at the heart of every bottled water plant. These facilities follow strict purification protocols and maintain rigorous quality control measures to ensure that every bottle meets the highest industry safety and hygiene standards.

Operating a bottled water plant offers clear advantages in responding to the growing need for clean and safe hydration. By utilizing advanced Water Testing Kits, producers can continually verify water purity, while connected Water Shops enhance public accessibility—making it easier for consumers to obtain premium bottled water.

This integrated approach reflects the industry’s unwavering commitment to delivering safe, dependable, and high-quality drinking water to communities.

Bottled Water Plants – A Response to Rising Contamination Concerns

The rapid expansion of bottled water plants stems largely from escalating concerns over water contamination. As pollutants and toxins continue to infiltrate natural water sources, conventional treatment methods often fall short in addressing the full spectrum of impurities.

To meet this challenge, bottled water facilities deploy advanced filtration and purification technologies, ensuring that every drop meets strict safety and quality standards. These plants serve as a dependable source of clean and safe drinking water, reinforcing consumer trust and promoting public health.

Meeting the Soaring Demand for Clean Drinking Water

The global need for clean and safe drinking water is at an all-time high, propelled by factors such as rapid population growth, urban expansion, and the escalating effects of environmental degradation. In many regions, limited access to clean tap water compels individuals to seek bottled water as a reliable and health-conscious alternative.

Bottled water plants play a vital role in addressing this challenge by producing large volumes of purified water, ensuring consistent supply and nationwide distribution to communities in need.

Upholding Quality Standards & Expanding Access to Safe Drinking Water

Ensuring Regulatory Compliance A major advantage of bottled water plants lies in their commitment to strict quality assurance protocols. Each batch of water undergoes comprehensive testing to confirm compliance with regulatory requirements for purity and safety. This meticulous approach provides consumers with confidence and peace of mind, knowing they’re drinking clean, high-quality water.

Providing Reliable Access to Clean Water Bottled water plants also serve as a convenient and dependable solution for accessing safe drinking water—particularly in areas with limited tap water infrastructure. Their products are easy to transport and store, making them ideal for households, commercial establishments, and emergency relief efforts. With these plants in operation, safe hydration is always within reach, no matter the circumstance.

Quality Assurance & Hygiene Protocols at Water Care Services Pakistan

Robust Quality Control Practices At Water Care Services Pakistan (WCSP), a comprehensive set of quality control measures is implemented across every phase of production—from water sourcing to final bottling. Each stage is rigorously monitored and tested to identify and eliminate potential contaminants or impurities, ensuring the water consistently adheres to the highest purity and safety standards.

Stringent Hygiene Standards In parallel with quality control, WCSP enforces strict hygiene protocols to safeguard product integrity. Bottling machinery is regularly cleaned and sanitized to prevent bacterial growth, while personnel receive specialized hygiene training to maintain cleanliness and operational discipline.

Through this unwavering dedication to safety and sanitation, WCSP guarantees that every bottle delivered to customers is safe, reliable, and ready for consumption.

Applications of Bottled Water Plants

🌿 Sustainable Practices in Bottled Water Production

While bottled water plants serve a vital role in providing safe drinking water, they can also exert pressure on the environment. At Water Care Services Pakistan (WCSP), we are committed to reducing this impact through the adoption of sustainable production practices. These efforts include minimizing water and energy consumption, enhancing the efficiency of packaging materials, and investing in renewable energy sources. Through these initiatives, we aim to lower our carbon footprint and help safeguard natural resources for future generations.

♻️ Recycling & Waste Management Initiatives

Beyond production, WCSP actively promotes recycling and responsible waste management as part of our broader sustainability mission. We collaborate with local communities to encourage recycling programs and reduce the volume of operational waste. This includes the recycling of bottles and packaging materials, and the safe disposal of residual waste generated during processing. By embracing these environmentally conscious practices, we contribute to a cleaner, healthier planet and foster long-term environmental responsibility.

Market Trends and Demand Analysis

Growth of Bottled Water Industry in Pakistan

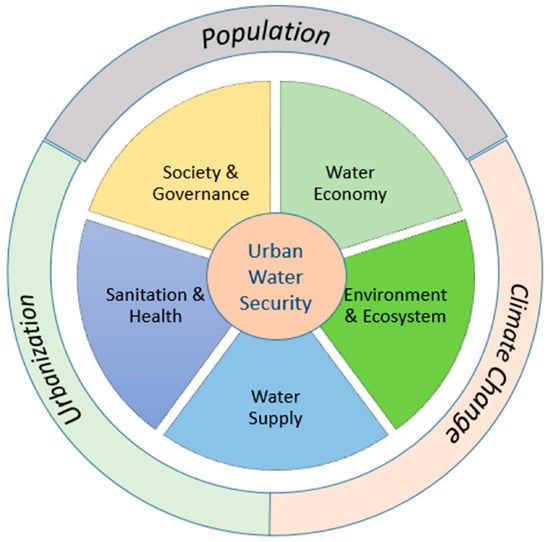

The bottled water industry in Pakistan has experienced significant growth in recent years, driven by increasing concerns over water quality and safety. As awareness of waterborne diseases and contaminants grows, more consumers are turning to bottled water as a safer alternative to tap water. This has led to a surge in demand for bottled water plants, as companies seek to capitalize on this growing market.

Factors Driving Demand for Bottled Water Plants

Several factors are driving the demand for bottled water plants in Pakistan. These include population growth, urbanization, industrialization, and environmental degradation. As the population continues to grow and urbanize, the demand for clean drinking water is expected to increase, creating opportunities for bottled water plant manufacturers. Additionally, concerns over water contamination and pollution are prompting both consumers and businesses to invest in bottled water solutions.

Future Outlook and Innovations in Bottled Water Plants

Emerging Technologies in Water Purification

The future of bottled water plants lies in the development of innovative technologies for water purification. Advancements in filtration, disinfection, and desalination are making it possible to produce even cleaner and safer drinking water. These technologies hold promise for improving water quality, reducing waste, and increasing efficiency in bottled water production.

Potential Market Expansion Opportunities

Looking ahead, there are several potential market expansion opportunities for bottled water plants in Pakistan. As awareness of water issues continues to grow, demand for bottled water is likely to increase, creating opportunities for new entrants and expansion of existing facilities. Additionally, technological advancements and changes in consumer preferences may open up new markets for bottled water products, such as flavored water, vitamin-enhanced water, and premium bottled water.

Conclusion

In conclusion, bottled water plants play a critical role in ensuring access to safe and clean drinking water in Pakistan. By addressing water contamination issues, meeting high demand for clean water, and adhering to strict quality and safety standards, these plants provide an essential service to communities across the country. As the bottled water industry continues to grow and evolve, Water Care Services Pakistan remains committed to providing innovative solutions that prioritize environmental sustainability and public health. We encourage individuals and businesses alike to invest in clean water solutions and join us in building a healthier and more sustainable future for all.

The primary function of a bottled water plant is to source, purify, and package water for consumer consumption, ensuring access to clean and safe drinking water.

Answer: Bottled water plants implement rigorous processes, including sourcing from clean water supplies and advanced purification methods, to ensure the quality and safety of the water they bottle.

Environmental concerns include the impact of plastic waste. To address this, bottled water plants are increasingly adopting eco-friendly packaging and water conservation measures.

Yes, bottled water plants are actively adopting sustainable practices, including the use of recycled materials for packaging, water conservation measures, and other eco-friendly initiatives.

Technological advancements, such as automation in manufacturing processes and advanced quality assurance technologies, enhance the efficiency and precision of bottled water production, ensuring a consistently high standard.

Absolutely. Bottled water plants prioritize the safety and purity of the water they provide, and many are actively addressing environmental concerns by adopting sustainable packaging solutions without compromising water quality.

Health and wellness trends, along with effective marketing and branding strategies, are driving consumer preferences in the bottled water industry, influencing choices and brand loyalty.

Yes, many bottled water plants offer a variety of water options, including flavored and enhanced waters, to cater to diverse consumer tastes and preferences.

Both small and large businesses have opportunities in the bottled water industry. The market is diverse, allowing for niche products and catering to various consumer preferences, creating space for businesses of all sizes to thrive.

Bottled water plants contribute to water conservation by implementing efficient production processes, recycling water used in production, and actively seeking ways to reduce water waste throughout their operations.