Electrocoagulation

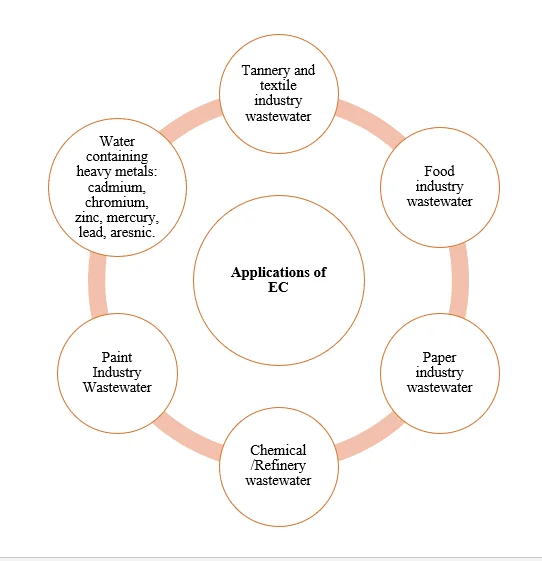

Electrocoagulation has been the focus of environmental sector for the last few years for the treatment of different types of wastewater as it combines the benefits of electrochemistry, coagulation and flocculation. It has become a potential technique for the treatment of industrial effluents due to its environmental compatibility, low cost, versatility and treatment efficiency.

Working Principal

Electrocoagulation is a complex process that involves a variety of pollutant removing mechanisms that operate synergistically. Several EC wastewater treatment projects have been initiated by WCSP team to determine the environmental and economic feasibility of wastewater treatment technology option in Pakistani industrial sector.

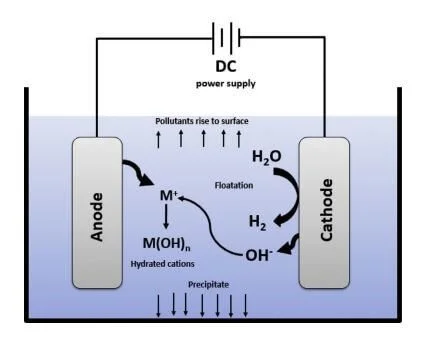

Electrocoagulation basically involves dissolution of metal cations from anode (1) with formation of hydroxyl ions (OH-1) and hydrogen gas at cathode (2) simultaneously.

M→ M+ + ne– (1)

2H2O (l) → OH-1 + H2 (g) (2)

A typical EC unit consists of an electrolytic cell as shown in figure 1. Anode and cathode metal electrodes are connected to DC power source externally and immersed in the solution to be treated. Most extensively used metal electrodes are iron and aluminum as these are non-toxic, reliable and easily available. When the DC current is passed through the cell, the sacrificial anode serves as the coagulant in the EC cell where it dissociates to give metal cations. Colloidal particles are destabilized by highly charged cations (Fe2+, Al3+) by the formation of monomeric and polymeric hydroxo complex species. These species have strong adsorbing properties resulting in formation of strong aggregates with pollutants.

Wastewater treatment with Electrocoagulation, ZLD, Biocleaner

Crafting an eco-friendly trifecta, the precision of Electrocoagulation, sustainable practices of Zero Liquid Discharge (ZLD), and the bio-friendly prowess of Biocleaner collectively redefine wastewater treatment, ensuring efficient purification with minimal environmental impact.

Advantages

- There is no chance of secondary pollution as no chemicals are added.

- Operation of EC is simple. Hence complete automation of process is possible.

- Treated wastewater is colorless, odorless and clear.

- Flocs formed by EC are easily separated during filtration as they are more stable and large than chemical coagulation/flocculation.

- EC technology removed toxic contaminants/heavy metals to non-detectable level.

- Lesser sludge volume is produced than chemical coagulation/flocculation.

- The removal of smallest colloidal particles is made possible by EC as the applied current makes collision faster and facilitates the process of coagulation.