Membrane Bioreactor

Membrane bioreactor (MBR) is a compact wastewater treatment technology for municipal and industrial wastewaters.

Membrane Bioreactor (MBR) is a space-efficient wastewater treatment solution designed for both municipal and industrial applications. It integrates biological treatment with advanced membrane filtration—using microfiltration and ultrafiltration techniques—to deliver superior water quality. The membranes function as precision filters, effectively removing solids produced during biological processes and yielding a clear, pathogen-free effluent.

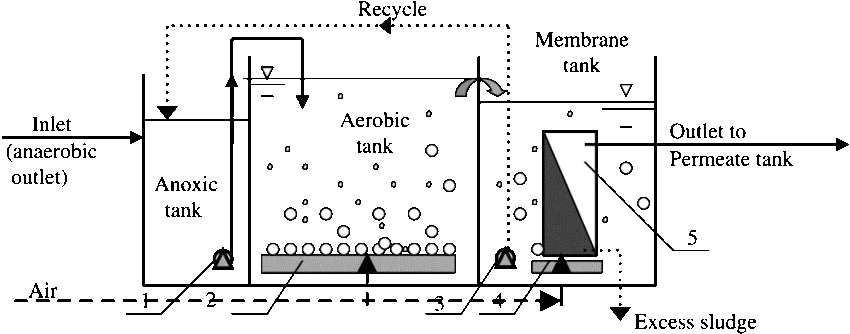

Compared to conventional treatment systems, MBR offers enhanced control over sludge bulking and ensures consistently high effluent quality. Figure 1 illustrates the schematic layout of a submerged MBR unit.

Advanced Water Treatment : MBR, Electrocoagulation, ZLD

Integrating the advanced capabilities of Membrane Bioreactors (MBR), the precise treatment control of Electrocoagulation, and the eco-efficient strategy of Zero Liquid Discharge (ZLD) creates a comprehensive water treatment approach—delivering high-purity output while significantly reducing environmental impact.

Applications of MBR

Membrane Bioreactors (MBRs) are particularly suited for untreated effluent streams containing easily biodegradable organic carbon—commonly found in the food and beverage industry.

MBR technology has been effectively implemented across various industrial sectors, including:

🧪 Pharmaceutical production, where wastewater contains active pharmaceutical ingredients (APIs)

📄 Pulp and paper processing, characterized by elevated levels of BOD, COD, and suspended solids

👕 Textile manufacturing, generating highly toxic and colored effluents

⛽️ Petroleum refining, with complex wastewater streams

🚢 Marine and shipping operations, dealing with shipboard wastewater