Have you ever wondered how industrial facilities manage water treatment processes efficiently while reducing operational costs?

The answer lies in the integration of automated chemical dosing systems—a game-changer for industries in Pakistan. With water treatment being a critical component in various sectors, including manufacturing, textile, and food processing, the demand for precision, consistency, and sustainability is higher than ever.

Recent advancements in smart industrial water treatment technology have made chemical dosing more accurate and cost-effective than traditional manual methods. In this blog post, we will explore how automated systems are revolutionizing water treatment in Pakistani industries, improving efficiency, lowering costs, and safeguarding the environment.

The Growing Need for Automated Chemical Dosing Systems

Industries in Pakistan face immense pressure to address water quality issues, especially in the wake of rapid urbanization and climate change. Manual dosing systems often lead to inaccuracies, overuse of chemicals, and increased waste. This not only impacts the environment but also escalates operating costs for businesses.

Automated dosing systems solve these issues by precisely regulating chemical doses based on real-time water quality data. With smart chemicals incorporated into the system, industries can automate water treatment processes, ensuring consistency and reducing the chances of human error.

How Automated Chemical Dosing Systems Work

What Is Automated Chemical Dosing?

At its core, automated chemical dosing involves the use of electronically controlled pumps and sensors that inject precise amounts of chemicals into water or wastewater systems. These chemicals could include coagulants, flocculants, pH adjusters, or disinfectants, depending on the specific treatment process.

Sensors monitor water quality in real-time, transmitting data to the dosing system, which adjusts chemical dosages accordingly. This continuous feedback loop ensures that the water treatment process remains optimal, reducing the risk of chemical wastage and overuse.

Key Features of Automated Dosing Systems

- Precision Control: Automated dosing systems can inject chemicals with pinpoint accuracy, based on the specific water quality measurements.

- Real-time Monitoring: Continuous data collection through sensors ensures that the system adjusts chemical dosages in real-time, preventing overdosing or underdosing.

- Data Integration: These systems integrate with the larger industrial control systems, providing operators with full visibility of the water treatment process.

- Remote Control: Many modern systems allow for remote monitoring and adjustments, offering flexibility and convenience for plant managers.

- Safety and Compliance: Automated systems help industries comply with environmental regulations by maintaining optimal water quality and minimizing chemical waste.

Benefits of Smart Chemical Dosing in Pakistani Industries

1. Cost Efficiency and Savings

Industries in Pakistan are always looking for ways to optimize operational costs. One of the biggest advantages of automated chemical dosing is the reduction in chemical consumption. By ensuring that chemicals are only used when necessary and in the right amounts, businesses can save significantly on chemical costs. Furthermore, optimized dosing reduces the wear and tear on water treatment equipment, leading to longer lifespans and fewer maintenance costs.

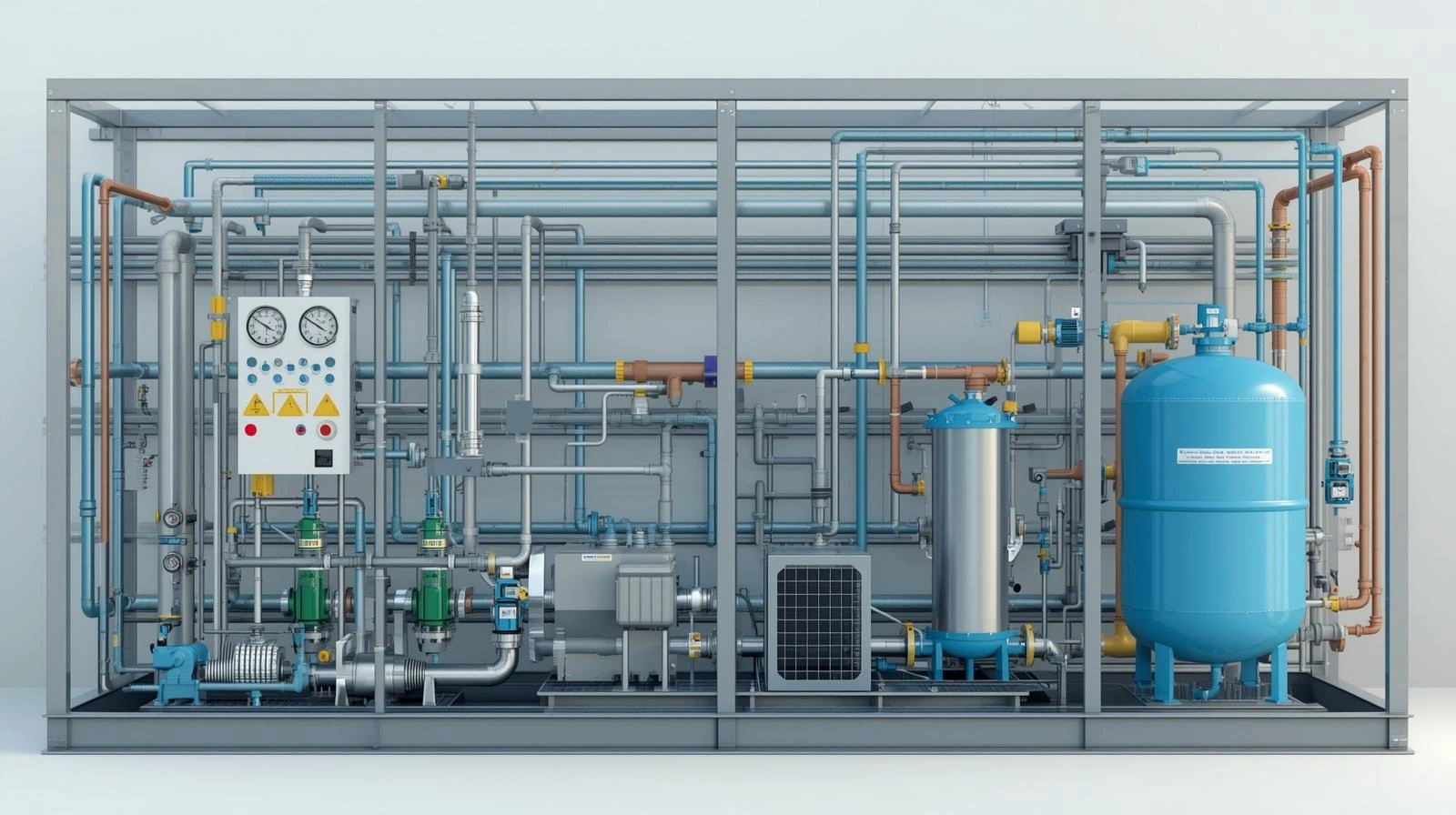

Chlorination System

2. Environmental Impact Reduction

Excessive chemical usage can be harmful to the environment, leading to pollution and contamination. Automated dosing minimizes chemical waste, promoting sustainable water management practices. This reduces the environmental footprint of industrial operations, which is increasingly important in today’s eco-conscious world.

3. Improved Water Quality and Consistency

With automated systems, water treatment processes are not left to chance. The precision dosing ensures that water quality is consistently maintained, which is especially important for industries such as textiles, where water quality directly affects product quality. Automated systems ensure that the water used in production is treated to the required standards without fluctuation, improving product consistency.

4. Increased Operational Efficiency

Manual chemical dosing is not only labor-intensive but also prone to errors. Automated systems streamline the process, reducing the need for human intervention while improving overall efficiency. This allows industrial facilities to focus on core operations and other strategic tasks, rather than constantly monitoring chemical dosing levels.

5. Scalability

As industries grow, the demand for more water treatment capacity increases. Automated dosing systems can be easily scaled to meet growing needs, whether through additional sensors, larger dosing pumps, or more advanced software. This flexibility allows companies to keep up with growing production demands without needing to overhaul their entire water treatment setup.

Real-World Applications in Pakistan

Case Study 1: Textile Industry

In Pakistan’s textile industry, water treatment is a crucial part of the manufacturing process. One major textile manufacturer implemented an automated chemical dosing system to improve its effluent treatment process. By optimizing chemical usage, the company reduced its chemical costs by 20% and lowered water wastage by 30%. This not only led to cost savings but also helped the company meet stricter environmental regulations.

Case Study 2: Food Processing Plants

A large food processing plant in Karachi faced challenges with maintaining consistent water quality for its production lines. After installing an automated dosing system, the plant was able to maintain the required water quality with minimal chemical use, reducing costs and improving the safety of its products. The system’s real-time monitoring capabilities ensured that the water treatment process was always in compliance with food safety standards.

Case Study 3: Manufacturing Facilities

A major manufacturing facility in Lahore used automated dosing to address challenges with scaling in its cooling tower systems. By reducing the overuse of chemicals like scale inhibitors, the company was able to prevent scaling issues, extend the life of its equipment, and reduce maintenance costs.

Key Considerations When Implementing Automated Dosing Systems

While automated chemical dosing systems offer numerous benefits, there are a few important factors to consider before implementation:

- System Integration: Ensure that the dosing system integrates smoothly with existing water treatment infrastructure. Compatibility with other industrial control systems is essential for maximizing efficiency.

- Training: Operators need to be adequately trained to monitor and adjust the system when needed. Although automated, these systems still require oversight.

- Regular Maintenance: While these systems reduce the need for manual labor, regular maintenance is essential to ensure the sensors and pumps remain accurate and effective.

Conclusion

Automated chemical dosing systems are transforming industrial water treatment in Pakistan. These smart systems provide precise, real-time control over chemical use, improving water quality, reducing environmental impact, and lowering operational costs. By embracing automation, industries can not only achieve significant cost savings but also improve their sustainability and compliance efforts.

If you’re considering upgrading your industrial water treatment system, automated dosing is the way forward. With its scalability, efficiency, and eco-friendly approach, it’s an investment that pays off in the long term.

FAQ Section

1. What are automated chemical dosing systems?

Automated chemical dosing systems use electronic pumps and sensors to precisely inject chemicals into water or wastewater systems based on real-time quality measurements, improving efficiency and reducing waste.

2. How do smart chemical dosing systems help reduce costs?

By optimizing the amount of chemicals used and ensuring accurate dosing, these systems reduce chemical waste and minimize operational costs, leading to significant savings.

3. What industries benefit from automated dosing systems?

Industries like textiles, food processing, and manufacturing can benefit from automated chemical dosing, as it ensures optimal water treatment while reducing costs and environmental impact.

4. Can automated dosing systems be integrated with existing infrastructure?

Yes, these systems are designed to integrate seamlessly with most industrial water treatment setups, improving efficiency without requiring a complete overhaul of existing systems.

5. How do automated dosing systems improve environmental sustainability?

By minimizing chemical waste and optimizing water treatment processes, automated dosing systems help reduce the environmental footprint of industrial operations, promoting sustainable practices.