Biocleaner

BioCleaner is a wastewater treatment system. It uses natural bacteria to treat the wastewater of all forms. The treatment unit can treat all types of wastewater i.e. residential, commercial, industrial and municipal wastewater.

BioCleaner is also effective in the treatment of waterways such as rivers, lakes, and ponds.

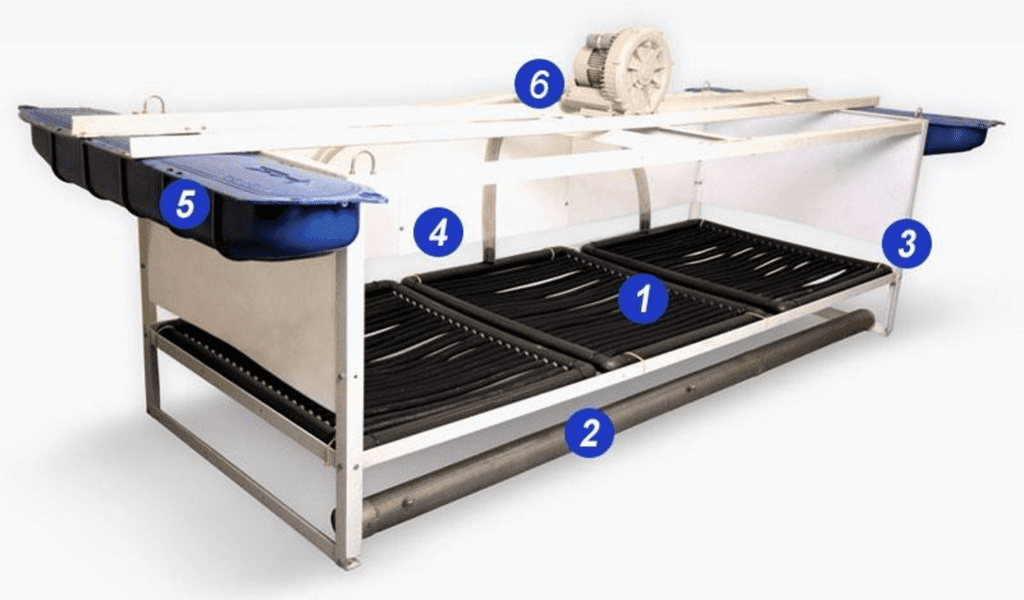

Components of BioCleaner

- Aerogrid is made of HDPE plastic. It comes with 66’ aerotube (aeration tubbing) which is attached using stainless steel clamps. The size of this grid is 1m x 2m.

- Biotubes are microbial bioreactors made of perforated stainless steel cylinders. They are 10 feet in length and 4 inches in These Biotubes are filled with a media made of ceramic material. Diffusers for aeration are located through the entire length of Biotube for the provision of oxygen to the microbes. The air blower used is only of 55 W power.

- Fiberglass angle bars are used in framing, each of which is 2inch x 2inch x 3mm in size. They are lightweight and heavy duty bars that can be submerged into almost any contaminant water. Long life and stands best against all kind of corrosive nature of effluents

- Polyethylene (PE) plastic walls cover about ¾ of the lift, comprised of four sheets that are 3.28ft x 2ft x 2mm each. These provide water direction and

- Planktons are made of PE plastic that is 61 inches in length, 12 inches in width and 8 inches in height. The planktons provide buoyancy to the system in order to make it mobile and consume less power.

- The Air Blower is a single phase motor, which uses 1.75kW of power. This motor will transport 240m³ air/hr. Approximately 3.65 kg O2/hr is transferred into the surrounding water.

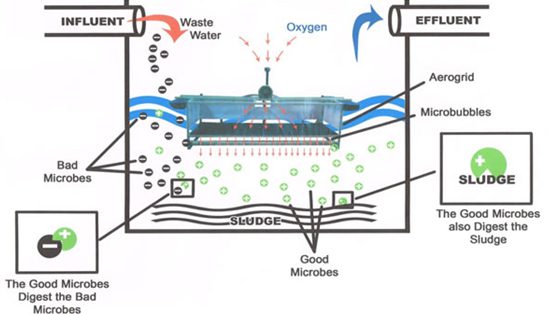

How Biocleaner Works

The BioCleaner is composed of parts that together create an efficient system that treats wastewater problems. The microbes that are used are stored in porous ceramic pellets which prevent them from being contaminated. These pellets, in turn, are stored in a tube called a “biotube”. With back pressure, the grids aerate and produce fine bubbles rendering the water less dense, while the surrounding water is denser. This causes the water to transfer to where there is less density, pulling the water up together with the microbes that then spread throughout the surface water, enabling the microbes to clean the water.

BioCleaner constantly produces microbes eliminating the need to add new microbes every day. The microbes are all-natural and have not been genetically modified. The microbes are safe from pathogens and from the risk of mutation. BioCleaner uses only microbes classified as Biosafety Level 1.

All of BioCleaner’s microbes are saprobic and facultative; taking their nutrition from the dead remains of other organisms. They are either anaerobic or aerobic. Different sets of microbes are used to reduce and eliminate non-toxic and toxic waste. When microbial tubes have generated enough microbial density to counter the “bad” microbes in the system, it treats the wastewater.

BioCleaner can treat water to the level that it can be reused i.e. for irrigation, boiler, cooling tower etc. The treated wastewater meets the criteria of National Environment Quality Standards.

In the realm of wastewater treatment, Biocleaner introduces an innovative ecological approach. Explore how our commitment to excellence is further emphasized through Real-Time Monitoring, ensuring transparency and efficiency, while adhering to the highest industry standards outlined in our Service Level Agreement (SLA). We also provide the service of Beverage Industry Wastewater Treatment & Chemical Free Water Treatment for better wastewater treatment.

Advantages

- No Bad Odor

- No Sludge Production

- Low Operation Cost

- Treating Wastewater to Desired Level

- Low Cost of Capital Acquisition

- Low Maintenance Cost

- No Labor Cost

- Lower Foot Prints

- No Need of Digesting Enzymes

- Environmental Friendly Technology