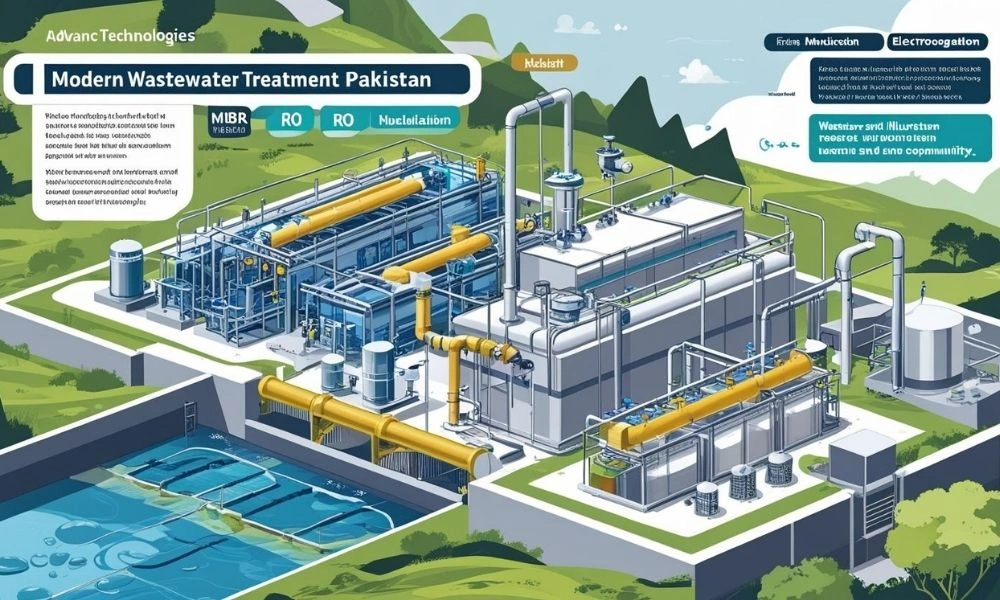

Wastewater treatment plants are essential for clean water, environmental safety, and legal compliance in Pakistan. WCSP provides advanced, scalable WWTP solutions using technologies like MBBR, RO, and electrocoagulation. Their systems treat industrial and municipal waste efficiently, enabling water reuse and protecting resources. Ideal for industries and communities aiming for sustainable water management.

Wastewater Treatment System

What is a Wastewater Treatment Plant (WWTP)?

A wastewater treatment plant, WWTP, is a plant that treats and cleans up used water, which has been made safe for discharge or reuse. These are systems that eliminate physical, chemical, and biological impurities in water from domestic, factory, or commercial sources.

WWTPs are essential in safely handling water, particularly in nations such as Pakistan where water pollution and scarcity are key issues. Relying on trusted technologies, wastewater is converted into sanitary, reusable water — aiding environmental and economic objectives alike.

Why Are Wastewater Treatment Plants Necessary in Pakistan?

Pakistan’s Water Crisis

Pakistan experiences a critical shortage of water, making it among the top 10 nations likely to run out of clean water. Domestic and industrial waste is polluting rivers, lakes, and groundwater because it is not treated.

Industrial Development and Pollution

Textile, leather, fertilizer, and pharmaceutical industries emit chemical-laden wastewater. This is released without treatment into rivers and agricultural fields, causing:

- Water-borne diseases

- Crop loss

- Pollution of drinking water sources

Legal Requirements

The Pakistan Environmental Protection Agency (EPA) has made it mandatory for industries to install wastewater treatment plants and adhere to National Environmental Quality Standards (NEQS).

Types of Wastewater Treatment Plants

1. Municipal Wastewater Treatment Plants

Utilized by towns and cities to treat residential sewage prior to discharging it into rivers or the sea.

2. Industrial Wastewater Treatment Plants

Tailor-made systems used to treat wastewater from factories, such as toxic chemicals, heavy metals, and sludge.

3. Combined Treatment Plants

Treat both industrial and municipal waste, particularly in mixed-use areas.

How Do WWTPs Work? Step-by-Step Process

Stage 1 – Preliminary Treatment

- Screening and Grit Removal

- Removes plastics, stones, and other solid waste

- Protects downstream equipment

Flow Equalization

- Stabilizes flow fluctuations and pollution load

- Avoids sudden shock to biological systems

Stage 2 – Primary Treatment

Sedimentation Tanks

- Heavier solids settle at the bottom as sludge

- Oil and grease float to surface and are skimmed off

Adjustment of pH

Balances alkalinity or acidity for subsequent treatment

Stage 3 – Secondary Treatment

Biological Treatment (MBBR, SBR)

- Breaks down organic waste using bacteria

- WCSP employs state-of-the-art MBBR (Moving Bed Biofilm Reactor) for high efficiency

Aeration Systems

- Inject oxygen to facilitate bacterial processes

- Decreases Biological Oxygen Demand (BOD)

Stage 4 – Tertiary Treatment

Filtration and Disinfection

- Sand filters remove the remaining solids

- UV, chlorine, or ozone disinfect the water

Stage 5 – Sludge Handling

- Dewatering and drying of sludge

- Can be applied to compost, incinerate, or landfill safely

A Balance in Blue & Greens

Blue Economy

Green Economy | Green & Blues | Water Care Services

Sustainability and Water Credits

Water Treatment

News&Events

Zoom Meeting

Wastewater Treatment for Agriculture

Water For Masses

Technologies WCSP Implements in WWTPs

✅ Bioremediation

- Introduces naturally occurring bacteria that feed on waste

- Environmentally friendly and low maintenance

✅ AOP (Advanced Oxidation Process)

- Remediates poisonous, non-biodegradable chemicals

- Uses ozone, UV, or hydrogen peroxide

✅ Electrocoagulation

- Removes suspended particles using electrical current

- Removes heavy metals, oil, and grease chemically free

✅ MBBR Technology

- Compact high-rate biological treatment system

- Suitable for small as well as large industries

✅ Reverse Osmosis (RO)

- Final purification step

- Eliminates dissolved salts, heavy metals, and toxins

Industries That Need Wastewater Treatment

Textile & Garment Factories

Employ dyes, detergents, and bleaches that contaminate water.

Pharmaceutical Industry

Generates chemical-rich wastewater containing active drug components.

Leather Tanneries

Produce chromium-loaded waste and biological impurities.

Food & Beverage Plants

Generate high BOD/COD water due to organic waste.

Chemical and Fertilizer Plants

Release toxic water with nitrates, sulfates, and solvents.

Advantages of Installing WCSP’s Wastewater Treatment Plants

✅ Environmental Protection

Reduces aquatic life pollution and water pollution.

✅ Regulatory Compliance

Complies with EPA and NEQS standards. Evades shutdowns and fines.

✅ Cost Savings

Treated water can be reused as:

- Boiler feed

- Cooling systems

- Gardening

- Toilet flushing

✅ Reputation & CSR

Sustainable practices enhance brand image and earn green-friendly clients.

✅ Customizable & Scalable

WCSP provides small to large-scale solutions based on your industry size and requirement.

Conclusion

Investing in an effective wastewater treatment plant is no longer a choice — it’s a must for any industry looking to achieve long-term success in Pakistan. WCSP provides access to cutting-edge, trustworthy, and affordable wastewater solutions right at your doorstep. From municipal-level systems to full-scale plants, their technologies guarantee cleaner water, regulatory compliance, and a greener future for everyone.

Frequently Asked Questions (FAQs)

1. What is a wastewater treatment plant (WWTP)?

A WWTP is a system that removes pollutants—physical, chemical, and biological—from used water, making it safe for reuse or disposal, and protecting the environment and public health.

2. Why are wastewater treatment plants critical in Pakistan?

Pakistan faces water shortages and heavy pollution. WWTPs help by cleaning domestic and industrial wastewater, reducing disease, protecting rivers, and ensuring legal compliance with EPA and NEQS standards.

3. What are the main types of WWTPs?

There are municipal plants for city sewage, industrial plants for toxic waste, and combined systems for areas with both residential and industrial discharge, each tailored for specific contamination types.

4. How does the wastewater treatment process work?

It involves five stages: preliminary (screening), primary (sedimentation), secondary (biological treatment), tertiary (filtration/disinfection), and sludge management—each step removes specific pollutants to produce clean water.

5. What technologies does WCSP use in WWTPs?

WCSP uses advanced tech like MBBR, electrocoagulation, AOP, bioremediation, and RO. These ensure high treatment efficiency, chemical-free operation, and compliance with environmental regulations.

6. What industries require WWTPs the most in Pakistan?

Textile, pharmaceutical, leather, chemical, fertilizer, and food processing industries generate high-pollutant wastewater needing treatment to prevent environmental damage and meet EPA guidelines.

7. What is MBBR and how does it help?

Moving Bed Biofilm Reactor (MBBR) uses biofilm carriers in aeration tanks for efficient biological treatment. It’s space-saving, energy-efficient, and ideal for industrial and urban wastewater applications.

8. How does electrocoagulation work in WWTPs?

Electrocoagulation uses electric current to remove suspended solids, oils, and heavy metals from wastewater. It’s effective, eco-friendly, and reduces chemical use in treatment processes.

9. Can treated wastewater be reused?

Yes. Treated wastewater can be reused for boiler feed, cooling, gardening, flushing, or construction, helping industries reduce fresh water consumption and save on operational costs.

10. Why choose WCSP for wastewater treatment solutions?

WCSP offers customizable, advanced, and cost-effective WWTPs using cutting-edge technology. They ensure regulatory compliance, water reuse, low maintenance, and a long-term environmental and financial return on investment.