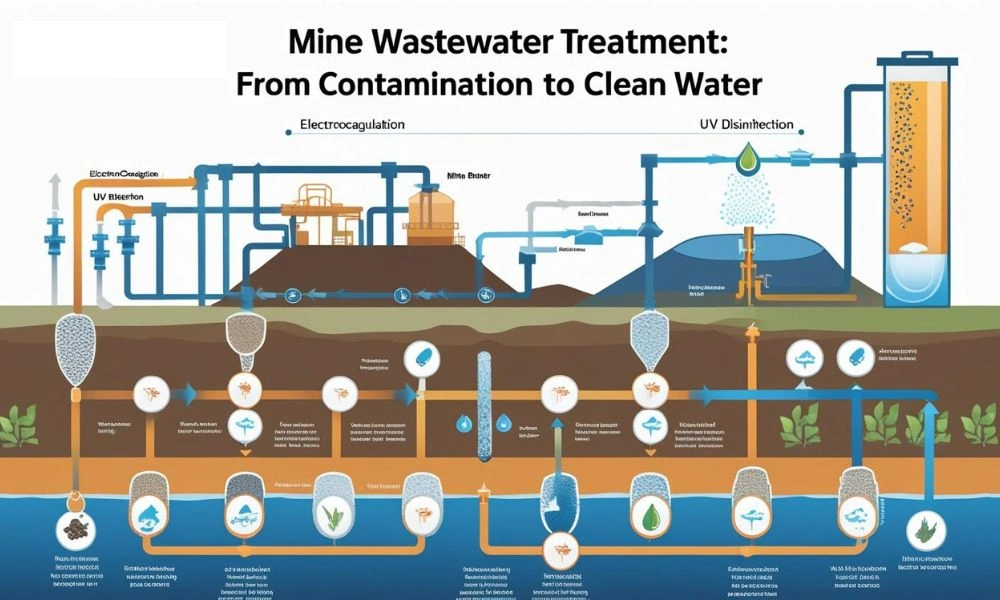

Turning mine wastewater into clean, drinkable water is no longer a dream. With advanced techniques like AOP, bioremediation, and electrocoagulation, WCSP delivers sustainable, efficient, and cost-effective water treatment solutions. Learn how this innovative approach ensures environmental safety, reduces resource waste, and provides communities and industries with a reliable, safe water supply.

What Is Waste Mine Water and Where Does It Originate?

Waste mine water is produced in the process of mining when groundwater or surface water interacts with mining activities. This water is contaminated with heavy metals, chemicals, and other toxic pollutants, thereby posing risk to human health and the environment if not treated.

Demineralization Water System

How Does It Affect the Environment and Public Health?

It can result in devastating effects like groundwater pollution, ecosystem destruction, and health hazards like skin diseases, organ injury, and long-term toxic exposure among local communities.

Is Waste Mine Water Actually Safe Drinking Water?

Is It Technical and Economically Possible?

Yes. With the recent developments in water treatment technologies, today it is technically and economically possible to treat mine water into clean drinking water. Organizations such as Water Care Services Pakistan (WCSP) are spearheading this change.

What Technologies Make This Possible?

WCSP employs a potent combination of:

- Bioremediation (green bacteria to break down pollutants)

- Electrocoagulation (electric current to coagulate and remove contaminants)

- Advanced Oxidation Processes (AOP) (oxidizes pollutants with hydroxyl radicals)

- MBBR (Moving Bed Biofilm Reactor for biological treatment)

Industrial Water Treatment Chemicals

Industrial Water Treatment Chemicals

Industrial Water Treatment Chemicals Industrial Water Treatment Chemicals by WCSP: Precision, Performance & Protection Water Care Services Pakistan (WCSP) offers a comprehensive range of industrial water treatment chemicals tailored to meet the demands of diverse

Industrial Water Treatment Chemicals

How Does WCSP Convert Waste Mine Water to Safe Drinking Water?

What Are the Primary Processes of WCSP?

WCSP’s process is a step-by-step one:

- First Screening: Grit removal and large solid materials.

- Electrocoagulation: To remove heavy metals and suspended solids.

- AOP: Organic toxin and pathogen degradation.

- Bioremediation & MBBR: Biological processes with specially engineered microbes.

- Polishing & Disinfection: Final filtration and chlorination/UV.

How Is Drinking Water Quality Guaranteed?

WCSP’s systems are ISO-certified, and all treated water is tested against Pakistan EPA and WHO guidelines before being declared safe for consumption.

Why Choose WCSP for Mine Water Treatment in Pakistan?

- Over 17 years of industry experience.

- Use of sludge-free, low-maintenance systems.

- Customizable and scalable solutions.

- Focus on energy efficiency and sustainability.

- Compliance with ISO 9001, 14001, and 45001 standards.

What Are the Economic and Environmental Benefits?

By converting waste mine water to potable drinking water, WCSP facilitates water recycling and lessens the reliance on freshwater resources—a major support pillar of the circular economy.

Can This Help Reduce Operational Expenses?

Yes. Treated mine water can be reutilized in industrial operations or diverted to nearby communities, saving a lot of water procurement expenses.

Exist Some Successful Case Studies in Pakistan?

One of WCSP’s Balochistan projects treated more than 200,000 liters daily of mine water, converting it to drinking water suitable for industrial reuse and consumption by local villages—accomplished at 50% less cost compared to conventional water acquisition processes.

Is the Process Safe Environmentally and Officially Approved?

WCSP adheres to:

- National Environmental Quality Standards (NEQS)

- ISO and WHO water safety standards

- Regular audits and third-party laboratory testing

What Is the Role of Innovation in WCSP’s Work?

WCSP goes on investing in R&D, automation, and IoT-based monitoring systems for optimizing operations and enhancing treatment efficiency in real-time.

Is It Scalable for All Mining Operations?

Yes. WCSP designs modular systems, with the benefit of having easy deployment of small units for remote operations or expansion for large-volume industrial mining operations.

Conclusion

Converting waste mine water into clean drinking water is not just achievable—it’s a must. Businesses like Water Care Services Pakistan have demonstrated that with the ideal combination of technology, talent, and vision, we can make a dangerous byproduct an asset of life. WCSP’s environmentally friendly and cost-effective solutions guarantee long-term reliability, sustainability, and regulatory compliance.

Frequently Asked Questions (FAQs)

1. What is waste mine water?

Waste mine water is water contaminated during mining operations by heavy metals, chemicals, and toxins. It originates from surface or groundwater entering mining sites and requires proper treatment.

2. Is waste mine water harmful to health?

Yes. It can cause severe health issues like skin diseases, organ damage, and long-term toxic exposure in nearby populations if left untreated.

3. Can waste mine water be made drinkable?

Yes. With modern technologies like AOP, electrocoagulation, and bioremediation, waste mine water can be treated to meet safe drinking water standards.

4. What technologies does WCSP use for treatment?

WCSP uses bioremediation, electrocoagulation, Advanced Oxidation Processes (AOP), and MBBR to remove contaminants and purify the water effectively.

5. Is WCSP’s treated water safe?

Yes. Treated water meets ISO, Pakistan EPA, and WHO standards through rigorous testing and quality control before distribution.

6. Is mine water treatment cost-effective?

Yes. WCSP’s solutions cut water procurement costs by up to 50% and enable water reuse, reducing long-term operational expenses significantly.

7. Is WCSP certified and compliant?

Yes. WCSP complies with ISO 9001, 14001, 45001 standards and NEQS, with regular third-party testing to ensure environmental and safety compliance.

8. Can small mines also use WCSP’s systems?

Yes. WCSP offers scalable, modular systems ideal for both small and large mining operations, including remote locations.

9. How does WCSP help the environment?

WCSP recycles waste water, reduces dependence on freshwater, and supports circular economy goals while minimizing environmental impact from mining.

10. Does WCSP use smart technologies?

Yes. WCSP integrates IoT-based monitoring and automation to enhance real-time efficiency and ensure consistent, high-quality water treatment performance.