Reverse Osmosis Plant

Reverse Osmosis Plant is designed to remove dissolved contaminants from the water source. It operates by directing water through a semi-permeable membrane driven by an applied force.

Brief Introduction of Reverse Osmosis Technology

Osmosis is an inherent process where water moves from a less concentrated area to a more concentrated one, and it occurs without the need for energy. On the other hand, reverse osmosis, which is the opposite of osmosis, demands energy. It requires higher pressure than the natural osmotic pressure to eliminate dissolved minerals or ions. In this method, pressure is exerted on the concentrated water area. While water molecules pass through the reverse osmosis membrane, it effectively captures contaminant molecules, such as dissolved solids. Once the dissolved minerals are removed, this water is known as demineralized water.

Application

The utilization of reverse osmosis plants spans across a broad range, serving both small and large-scale applications. Some highlighted industries are:

- Food industry

- Bottle and Beverage manufacturing unit

- Power Generation

- Boiler and Cooling tower systems

- Pre-treatment for various industries

- Pharmaceutical industries

- Medical sector

How does Reverse Osmosis Plant work

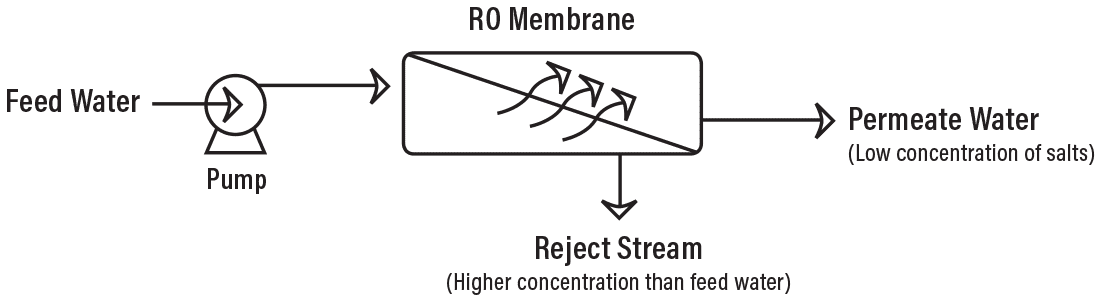

The reverse osmosis main working component is a semi-permeable membrane. RO working starting with the application of pressure through the pump on high TDS source water (Feed water). The concentration of salts present in feed water determined the amount of applied pressure. Higher salt concentration required higher pressure for succeeding over natural osmotic pressure. Feed water stream passing through a membrane under applied pressure. Removing almost all dissolved minerals in form of rejection stream. This ensures that the product water is devoid of any dissolved salts. The resulting water product is commonly referred to as permeate water.

Salient Features

Water Care Services, RO plants are compact, skid mounted, and long life. Some of the key features are:

- Remove dissolved solids at best level

- Reliable

- Highly efficient

- Operate at a low energy level

- Fully automatic System

- Long life due to solid and heavy duty parts

- Good documentation & online support

- Low operation and maintenance cost

- Removing up to 99%+ of the dissolved minerals (ions), particles, colloids, organics, and bacteria

- Reduction in scale formation

- Improved system performance

Who Is the Most Trusted Domestic RO Plant Company in Pakistan?

In determining a reliable local RO plant company in Pakistan, Water Care Services Pakistan (WCSP) is at the top of the list.

Here’s why:

- Founded in 2007 with nationwide credibility

- ISO-certified and internationally recognized technologies

- Expert in electrocoagulation, AOP, and bioremediation

- Offers customized home RO solutions with installation and maintenance support

- Transparent pricing and exceptional customer reviews

Their plants are designed for low maintenance, high performance, and long-term water purity. WCSP’s residential RO plants are tailored to accommodate local water conditions and customer prices.