Solid-liquid separation plays a vital role in modern mining by optimizing water recovery, reducing environmental impact, and enhancing processing efficiency. Integrated into smart mine design, these technologies ensure sustainability, regulatory compliance, and cost savings. Explore how separation methods like centrifuges, filter presses, and thickeners make future mining operations cleaner and more efficient.

Ultra-filtration Water Plant

Why Solid-Liquid Separation is Important?

Smart mine design aims to maximize performance, safety, and environmental sustainability. At the heart of this strategy is solid-liquid separation, an operation that converts slurry and mining effluent into recoverable water and workable solids. Strategically applied, it lowers water usage, risk of tailings, operating expenses, and environmental impact—all essential in contemporary mining.

Water Reuse & Conservation

Solid separation from process water makes its recirculation possible—essential in dry areas or water-constrained mines.

Tailings Volume Reduction

Reduced storage requirements minimize tailings dam size and related risk.

Operational Efficiency

Increased recovery rates, minimized chemical use, and extended equipment life.

Improved Safety & Compliance

Reduced tailings moisture and treated effluent simplify handling, enhance stability, and facilitate regulatory compliance.

Environmental Sustainability

Reduces discharge, minimizes environmental footprint, and promotes community water security.

Technologies & Applications

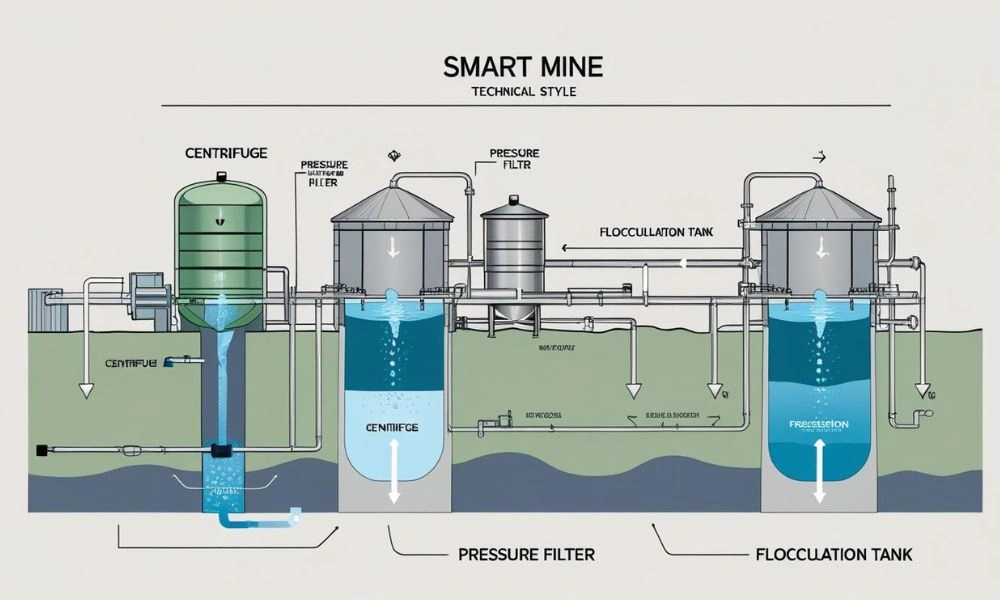

Centrifugal Decanters

High-speed separators well-suited for dewatering slurries with fluctuating solids.

Belt and Filter Presses

Create cake-like solids, facilitating easier handling and disposal.

Hydrocyclones

Compact, scalable equipment for coarse separation in initial processing.

Thickeners & Clarifiers

Utilized upstream for bulk solid settling; perfect pre-treatment prior to final dewatering.

Membrane Filters & Pressure Ozonation

Polishing for ultra-clean, reusable water.

Smart Mine Integration

A smart mine employs real-time sensors and automated controls to track slurry density, moisture, and water quality. Implementing solid–liquid separation within this system facilitates:

- Automated Feed Control for repeatable cake dryness.

- Data Analytics to forecast maintenance requirements and maximize energy.

- Remote Operation to minimize onsite staff in risky areas.

- IoT-Driven Water Balance to monitor and save water consumption.

Advantages & Considerations

Area Benefits Considerations

Cost savings Reduced water purchase & disposal costs Increased upfront investment in sophisticated equipment

Risk reduction Decreased tailings capacity and dam breach risk Requires skilled training and upkeep

Eco-impact Lower effluent discharge and habitat effects Sludge disposal logistics need to be coordinated

Efficiency Faster recovery, less downtime Can be complicated to integrate with existing plants

Moving Bed Biofilm Reactor

Challenges & Strategies

- Capital Cost: Mitigated through long-term savings and environmental incentives.

- Maintenance Demand: Schedule automated cleaning, and sensor-based predictive maintenance.

- Operator Training: Create hybrid teams of process-water and mining specialists.

- Scale-up Needs: Test with pilot projects and modular units prior to full implementation.

Real-World Impact

- Fewer Dams & Less Risk: Lower tailings moisture enhances dam stability and public safety.

- Water Stewardship: Mines maintain operations in drought regions, generating local goodwill.

- Regulatory Support: Tighter discharge requirements render separation technologies a compliance advantage.

- Energy & Emissions: Cleaner water recirculation reduces pumping energy and greenhouse emissions.

Implementation Best Practices

- Site Assessment: Review feed properties and water chemistry.

- Techmix Strategy: Integrate hydrocyclones, centrifuges, filters, membrane polishing.

- Automation Integration: Embrace sensors for feed rate, moisture, turbidity.

- Water Balance Modeling: Model flows to maximize reuse and track losses.

- Lifecycle Planning: Incorporate sludge disposal, consumables, waste logistics into CAPEX/OPEX.

Solid-Liquid Separation in Smart Mine Case Study

- Challenge: Dry-site gold mine with water shortages and tailings safety issues.

- Solution: Commissioned thickener → centrifuge → belt filter train.

- Smart Add-ons: Turbidity sensors, moisture meters, and automated valves.

Results:

- 70% water reuse rate, cutting water purchases.

- 55% less tailings volume, allowing lower dams.

- Reduced downtime due to predictive warnings and cleaner feeds.

Conclusion

Solid–liquid separation is the foundation of intelligent mine design—opening the door to water efficiency, operating performance, environmental resilience, and safety. Coupled with automation and control based on data, such systems open up the door to future-proofed mining operations that harmonize profit with planet and people.

Frequently Asked Questions (FAQs)

1. What is solid-liquid separation in mining?

It’s the process of removing solids from slurry or wastewater to recover reusable water and produce manageable solids—boosting efficiency, safety, and environmental compliance.

2. Why is solid-liquid separation essential in mining operations?

It reduces water usage, enhances equipment life, lowers tailings risk, and ensures regulatory compliance—making mines safer, greener, and more efficient.

3. What are the benefits of solid-liquid separation?

Key benefits include reduced water costs, smaller tailings volume, improved environmental impact, faster processing, and enhanced safety standards.

4. Which technologies are commonly used for separation?

Common technologies include centrifuges, belt/filter presses, hydrocyclones, thickeners, clarifiers, and membrane filters for different stages of water-solid treatment.

5. How does solid-liquid separation support water reuse?

It extracts solids from process water, enabling clean water recirculation within the mine—crucial for drought-prone or water-scarce mining sites.

6. What is the role of smart technology in separation systems?

Smart mines use sensors, automation, and IoT to monitor slurry density, optimize feed rates, trigger maintenance alerts, and balance water usage in real-time.

7. What challenges come with these systems?

Initial costs, technical training, integration complexity, and sludge disposal logistics are the major challenges—though long-term gains outweigh them.

8. How does solid-liquid separation reduce tailings dam risk?

By lowering moisture content in tailings, it enhances dam stability and reduces breach risks—making operations safer for nearby communities.

9. What is a good implementation strategy?

Start with site assessment, choose the right tech mix (e.g., thickeners + filters), integrate automation, and plan for lifecycle costs like sludge handling.

10. What are real-world results of using solid-liquid separation?

Mines have achieved up to 70% water reuse, 55% tailings volume reduction, and fewer shutdowns—all contributing to lower costs and better ESG compliance.