Pharmaceutical effluent treatment: case study

Pharmaceutical effluent

“Pharmaceutical effluent” refers to the liquid waste or discharge produced during the manufacturing processes in the pharmaceutical industry. This effluent can contain various substances, including chemicals, drugs, and other contaminants used in the production of pharmaceuticals.

Pharmaceutical effluent treatment

“Pharmaceutical effluent treatment” specifically refers to the processes and technologies implemented to treat and manage the pharmaceutical effluent before it is discharged into the environment. The treatment aims to remove or reduce the concentration of harmful substances and contaminants present in the effluent, ensuring that the discharged water meets regulatory standards and does not pose environmental risks.

In short, “Pharmaceutical effluent” is the wastewater generated from pharmaceutical manufacturing, while “Pharmaceutical effluent treatment” involves the methods employed to treat and mitigate the environmental impact of this wastewater before it is released.

Pharmaceutical effluent treatment case study

Water is a critical raw material for pharmaceutical manufacturing processes, water treatment and reuse has been the utmost concern of the industry to ensure consistent and quality supply of water for various operations. In the recent years effluents are discharged directly into the sewage and water bodies without treatment. This has resulted in not only higher concentrations of drugs and antibiotics in effluent, groundwater, irrigated soil and plants but also the detection of antibiotic resistant genes in the receiving environment of the pharmaceutical effluent.

This project, executed by Water Care Services Pakistan, demonstrates the BioCleaner wastewater treatment system, a form of green technology that uses biological treatment to efficiently remove harsh chemicals and contaminants from the effluent stream of a pharmaceutical plant in Lahore.

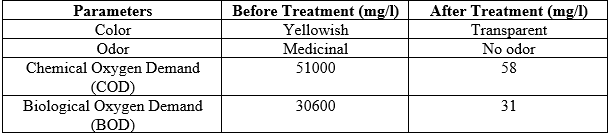

The results showed a remarkable reduction in BOD and COD parameters of the treated effluent by up to 99.8%. This indicates the effective removal of toxic pharmaceutical compounds (PCs) and active pharmaceutical ingredients (APIs), which are otherwise harmful to the environment and pose a risk of ecotoxicity. The treated water exhibited no odor, sludge, or chemical additions. Discharging the treated effluent into the surrounding environment not only reduced pollution in receiving water bodies but also improved the aquatic ecosystem, supporting species like fish and turtles due to increased dissolved oxygen (DO) levels. Furthermore, the treated water is now used for gardening and agricultural purposes.

In the pharmaceutical industry, sustainability is evident through initiatives like pharmaceutical effluent treatment for responsible wastewater disposal. Industries also prioritize air quality monitoring to minimize their carbon footprint and uphold environmental standards. Moreover, soil quality monitoring ensures the overall health of ecosystems, reflecting a holistic commitment to environmental protection.

Feed gas preparatory:

The feed gas can consist of either dry air or concentrated oxygen. Dry air is defined as air that has been dried to a dew point of -60°F or lower.

Concentrated oxygen refers to a purified gas containing a minimum of 90% oxygen, with all moisture thoroughly eliminated to ensure optimal performance in specialized applications.

Power input:

The primary power demand arises from the conversion of oxygen into ozone. Supplementary power needs encompass the preparation of feed gas, the ozone contact process, as well as the power necessary for control, instrumentation, and monitoring facilities.

Ozone generating device:

Ozone is typically generated on-site for disinfection purposes using a corona discharge method. The ozone is produced by applying high voltage between closely spaced electrodes, using either air or concentrated oxygen as the source.

The high-energy corona, generated through the process mentioned above, separates one oxygen molecule, which then combines with two other oxygen molecules to form an ozone molecule.

Using ambient air as the feed gas, this method generates an ozone concentration ranging from 1–3% by weight. When pure oxygen is used instead, the resulting ozone concentration increases significantly—typically between 3–10% by weight.

Contact basin:

The most critical process during use of ozone as the disinfectant is the proper mixing of ozone in the water. Two types of systems are used for this purpose i.e. ozone transfer via bubble diffusion or venture.

Bubble diffusion refers to the ozone transferred by diffusers. The diffusers create small bubbles of ozone in water. As the bubble rises, the gas at the edge of the bubbles will transfer into the water.

Venturi injection system work by forcing water through the conical body. This process creates a pressure differential between inlet and outlet ports resulting in a vacuum inside the injector body.

This vacuum effect enables the swift induction of ozone through the designated suction port, ensuring efficient mixing within the system.

Feed gas preparatory:

The feed gas can consist of either dry air or concentrated oxygen. Dry air is defined as air that has been dried to a dew point of -60°F or lower.

Concentrated oxygen refers to a purified gas containing a minimum of 90% oxygen, with all moisture thoroughly eliminated to ensure optimal performance in specialized applications.

Power input:

The primary power demand arises from the conversion of oxygen into ozone. Supplementary power needs encompass the preparation of feed gas, the ozone contact process, as well as the power necessary for control, instrumentation, and monitoring facilities.

Ozone generating device:

Ozone is typically generated on-site for disinfection purposes using a corona discharge method. The ozone is produced by applying high voltage between closely spaced electrodes, using either air or concentrated oxygen as the source.

The high-energy corona, generated through the process mentioned above, separates one oxygen molecule, which then combines with two other oxygen molecules to form an ozone molecule.

Using ambient air as the feed gas, this method generates an ozone concentration ranging from 1–3% by weight. When pure oxygen is used instead, the resulting ozone concentration increases significantly—typically between 3–10% by weight.

Contact basin:

The most critical process during use of ozone as the disinfectant is the proper mixing of ozone in the water. Two types of systems are used for this purpose i.e. ozone transfer via bubble diffusion or venture.

Bubble diffusion refers to the ozone transferred by diffusers. The diffusers create small bubbles of ozone in water. As the bubble rises, the gas at the edge of the bubbles will transfer into the water.

Venturi injection system work by forcing water through the conical body. This process creates a pressure differential between inlet and outlet ports resulting in a vacuum inside the injector body.

This vacuum effect enables the swift induction of ozone through the designated suction port, ensuring efficient mixing within the system.