Packaged Type WasteWater Treatment System

Advancing Water Quality Through Integrated Treatment Solutions

Water’s role as a universal solvent makes it indispensable across drinking, agricultural, and industrial applications—making the assurance of water quality a matter of critical importance. Rising demand for clean water, coupled with stricter environmental regulations, has spurred the evolution of innovative water treatment technologies.

Among these, the Packaged Type Water Treatment System stands out as an all-in-one solution capable of efficiently treating both surface water and wastewater. Its compact, modular design enables easy deployment across diverse settings, delivering effective purification in a streamlined format.

Sustainable Impact with No Sludge Treatment Technology

Integrating No Sludge Treatment with packaged water systems represents a significant step forward in sustainable water management. This approach minimizes waste, reduces environmental impact, and upholds high purification standards. By combining these technologies, water treatment becomes cleaner, more efficient, and resource-conscious, offering an ideal solution for modern infrastructure and environmental sustainability.

Packaged Type Water Treatment System: A General Discussion

Packaged Type Effluent Treatment Plant (ETP) – Compact, Efficient & Customizable

Our Packaged Type Effluent Treatment Plants (ETPs) come equipped with key features designed to optimize space, efficiency, and performance. One of the standout functionalities is the recycling and reuse of wastewater from car wash stations, providing an eco-friendly solution that conserves water and reduces discharge.

Key Highlights:

Best-in-Class Car Wash Wastewater Recycling

Compact Footprint – Ideal for space-constrained areas

Portable & Pre-Engineered – Easy to relocate and install

Upgrade Your Filtration System—Get Professional Guidance Now

Applications of Packaged Type Water Treatment System

Versatile Applications of Packaged Water Treatment Systems

Packaged Water Treatment Systems are compact, modular solutions capable of treating a variety of water sources, including surface water, groundwater, and wastewater. Their adaptability and efficiency make them suitable for a wide range of environmental and industrial contexts.

Surface Water Treatment

These systems effectively process water from rivers, lakes, and reservoirs through integrated steps such as:

Coagulation

Flocculation

Sedimentation

Filtration

Disinfection

Groundwater Treatment

For treating contaminated groundwater, packaged systems typically employ:

Filtration

Activated Carbon Adsorption

Ion Exchange

Disinfection

Wastewater Treatment

Widely used for industrial and municipal effluent, these systems incorporate a blend of:

Physical (e.g., sedimentation)

Chemical (e.g., flocculation)

Biological (e.g., biodegradation) processes These systems can even deliver reusable water, meeting stringent quality standards for reuse.

Packaged Type MBBR STP: An In-Depth Solution

MBBR STP Packaged System – Efficient, Compact & Versatile Wastewater Treatment

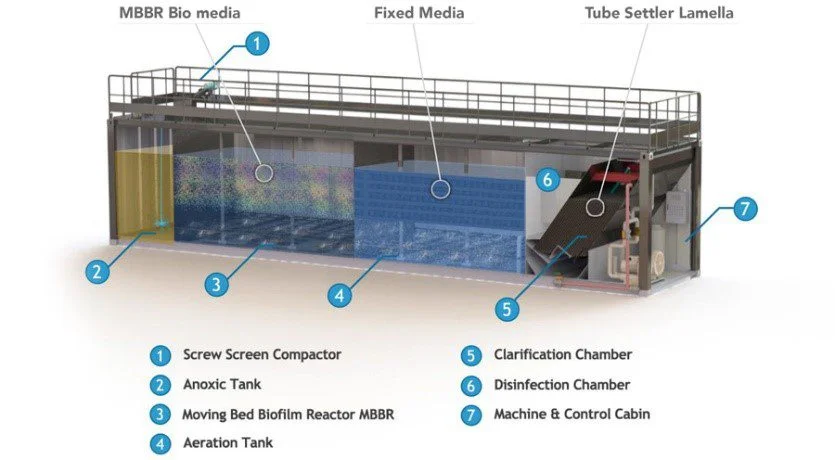

One of the most widely adopted solutions in wastewater management is the MBBR Sewage Treatment Plant (STP) configured as a Packaged System. Based on Moving Bed Biofilm Reactor (MBBR) technology, this system combines biological and physical processes to treat wastewater effectively.

At its core, the system features a reactor tank filled with floating plastic media, specially designed to support the growth of biofilm microorganisms. These carriers provide an extensive surface area, which significantly enhances microbial activity and treatment efficiency. Their continuous movement within the tank creates turbulence, ensuring uniform distribution of microorganisms and thorough mixing of the wastewater.

As a pre-engineered, self-contained unit, the MBBR STP Packaged System comes fully assembled—facilitating easy installation, streamlined operation, and minimal setup time.

Reliable Performance Across Diverse Applications

Engineered for consistent and dependable operation, this system is ideal for facilities requiring uninterrupted wastewater treatment. It can process high organic loads, making it well-suited for industries such as:

Food and beverage manufacturing

Pharmaceutical production

Petrochemical processing

Benefits of Packaged Type System

Key Features of the Compact Packaged Type Water Treatment System

Space-Efficient Design – Compact layout ideal for constrained installations

Automated Operation – Intelligent control systems ensure hassle-free functionality

High-Efficiency Treatment – Delivers consistent purification performance

Fully Portable Unit – Engineered for mobility and off-site deployment

Easy Relocation – Simplifies installation and repositioning in diverse settings

Low Energy Consumption – Designed for optimized power efficiency

Pre-Engineered Construction – Factory-assembled for faster deployment

Pre-Fabricated Build – Integrated systems minimize on-site labor

Minimal Maintenance Requirements – Requires only basic upkeep for sustained operation

Conclusion

Packaged Type Water Treatment Systems – Compact, Versatile & Cost-Efficient

Packaged water treatment systems provide a comprehensive, all-in-one solution for treating both surface water and wastewater. These compact, pre-engineered, and skid-mounted units are designed for easy transport, rapid installation, and streamlined operation, making them ideal for locations with space or infrastructure constraints.Systems such as the MBBR Sewage Treatment Plant (STP) exemplify the efficiency and dependability of this approach, delivering robust performance for small to medium-sized projects.

Rising Demand & Strategic Deployment

With the growing need for clean water and the tightening of regulatory standards, packaged systems have become a strategic asset in modern water management. Their low capital expenditure (CAPEX) and operational expenditure (OPEX) make them an attractive solution for budget-conscious deployments.

Proven Experience in Nationwide Projects

Water Care Services Pakistan (WCSP) has successfully implemented numerous packaged system projects across the country, leveraging the design’s durability, portability, and cost-effectiveness. Their work reflects a commitment to accessible, sustainable water treatment for communities and industries alike.