Moving Bed Biofilm Reactor

Moving Bed Biofilm Reactor (MBBR) is an advanced biological wastewater treatment process that integrates biofilm carrier technology with the conventional activated sludge method. This highly effective treatment system is designed to handle high organic loading rates and can operate under both aerobic and anaerobic conditions. The MBBR process offers enhanced treatment efficiency, reduced footprint, and operational flexibility, making it ideal for both municipal and industrial wastewater applications.

MBBR Design Components

Key Components of MBBR Systems

Basin (Reactor/Aeration Tank): The basin, also called a reactor or aeration tank, serves as the central vessel for the Moving Bed Biofilm Reactor (MBBR) process. Its size is designed based on the plant’s filtration requirements. Typically open at the top, the tank creates an aerobic environment that supports efficient biological treatment.

Media (Carriers): The basin is filled 50–70% with specially designed plastic media, known as carriers, which match water density for uniform dispersion. Biofilm forms on their surfaces, providing a large active area for microbial activity and enhancing the breakdown of pollutants, ensuring effective wastewater treatment.

Aeration Grid Positioned at the bottom of the reactor, the aeration grid comprises fans or diffusers that ensure consistent media movement within the fluid. It also facilitates the introduction of oxygen, supporting aerobic conditions and maximizing biological treatment efficiency.

Sieve Assembly A sieve made of mesh material is installed to retain the plastic media within the basin while permitting the treated water to exit freely. This component is crucial for maintaining media integrity and ensuring seamless flow dynamics.

Advantages of MBBR

MBBR – A Compact, Efficient & Eco-Friendly Wastewater Treatment Solution

Space-Saving Design The Moving Bed Biofilm Reactor (MBBR) is an ideal solution for facilities with limited space, thanks to its compact footprint. Despite its smaller size, it delivers treatment efficiency comparable to larger systems, utilizing high-surface-area media that foster optimal biofilm growth.

Naturally-Driven & Straightforward Operation By harnessing natural biological processes, MBBR ensures a simple and intuitive operation. The system allows microorganisms to thrive and treat wastewater with minimal external intervention.

Low Maintenance & Self-Regulating MBBR stands out as a low-maintenance, self-moderating technology, minimizing the need for frequent oversight and complex operational inputs—making it highly suitable for diverse facility types.

Resilience to Load Variations The system offers excellent flexibility, capable of adapting to shock loads and sudden pH fluctuations, maintaining consistent performance even under challenging conditions.

Efficient & Sustainable Performance With its high biological efficiency, MBBR ensures effective wastewater treatment while remaining environmentally and economically sustainable, promoting responsible water management.

Request a Free Consultation for Your Water System Needs

Industrial Application

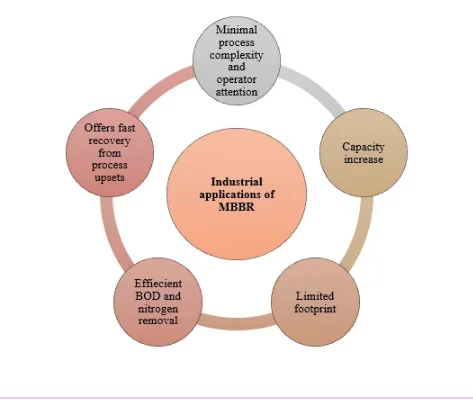

Industrial Applications of MBBR Technology

The Moving Bed Biofilm Reactor (MBBR) system is highly effective for onsite wastewater treatment across a wide spectrum of industries. It is commonly deployed in sectors such as:

Paper and pulp

Chemical manufacturing

Dairy processing

Textile production

Beverage manufacturing

MBBR systems are specifically designed to address organic pollutants and reduce Biochemical Oxygen Demand (BOD) levels, ensuring efficient and regulatory-compliant treatment of industrial effluent.

Integrated Solutions for Enhanced Water Treatment Efficiency

Integrated Technologies for Advanced Wastewater Treatment

The combined use of Moving Bed Biofilm Reactor (MBBR), the Fenton Process, and Packaged Water Treatment Systems offers a holistic and high-performance solution for wastewater management. This synergistic approach enhances overall treatment efficiency, effectively targeting a wide range of organic and inorganic pollutants.

By integrating biological, chemical, and modular treatment methods, the system ensures optimal contaminant removal, operational flexibility, and scalability—making it highly suitable for industries seeking comprehensive water purification strategies.