Have you ever asked yourself: “How can my food-processing facility effectively handle wastewater without a sprawling costly treatment plant?”

Imagine a medium-sized food processing unit in Pakistan generating thousands of litres of effluent each day—high in organics, fats, cleaning chemicals—and facing increasing regulatory, cost, and space pressures. With water scarcity, stricter discharge rules and rising disposal bills, conventional bulky systems may no longer cut it.

Here’s the good news: by the end of this article you’ll understand exactly how a modular wastewater treatment solution can transform the situation. You’ll learn key design steps, real-world examples (including from Pakistan), and actionable take-aways you can implement right now to design—or select—the right packaged plant for your food processing operation.

Why should a food processing industry consider a modular wastewater treatment plant?

Key benefits & context

For a food processing business (especially in Pakistan’s food industry wastewater-context), adopting a modular wastewater treatment plant offers several clear advantages:

- Faster deployment & smaller footprint: Modular systems are factory-assembled and pre-configured, which cuts down on onsite construction time. For example, manufacturers such as EveraTREAT report up to a 10-35% cost saving compared to traditional build-onsite.

- Scalability & flexibility: As your production expands or changes product lines, a modular solution can be scaled by adding units or upgrading modules.

- Suitability for high-organic, variable loads: Food industry effluents often fluctuate in volume and composition (e.g., washdown water, blanching water, cleaning chemicals). Modular plants are adaptable to such variability.

- Compliance + reuse potential: In Pakistan, now more than ever, the environment and regulatory landscape demand compliance with the Pakistan Environmental Protection Agency (Pak-EPA) and the National Environmental Quality Standards (NEQS). Modular plants can help meet discharge criteria and even enable reuse of treated water.

- Cost savings over lifecycle: Lower construction cost, faster commissioning, and often lower O&M (via automation/remote monitoring) translate into better ROI. One lifecycle assessment in South Asia estimated that energy for treatment alone may range from 0.26 kWh/m³ to 0.64 kWh/m³.

Real-world example

The German company EnviroChemie supplied a modular water-treatment system to a Pakistani plant: “functional units … are preassembled in secure frames … the only additional requirement was the manufacture of the connecting pipework between units.”

This shows how modular design reduces on-site complexity.

Pro Tip

Before choosing a modular solution, map out your peak flow, organics load (COD/BOD), fat/oil content, cleaning chemical load, and space constraints. These parameters will determine module size, process train, and cost.

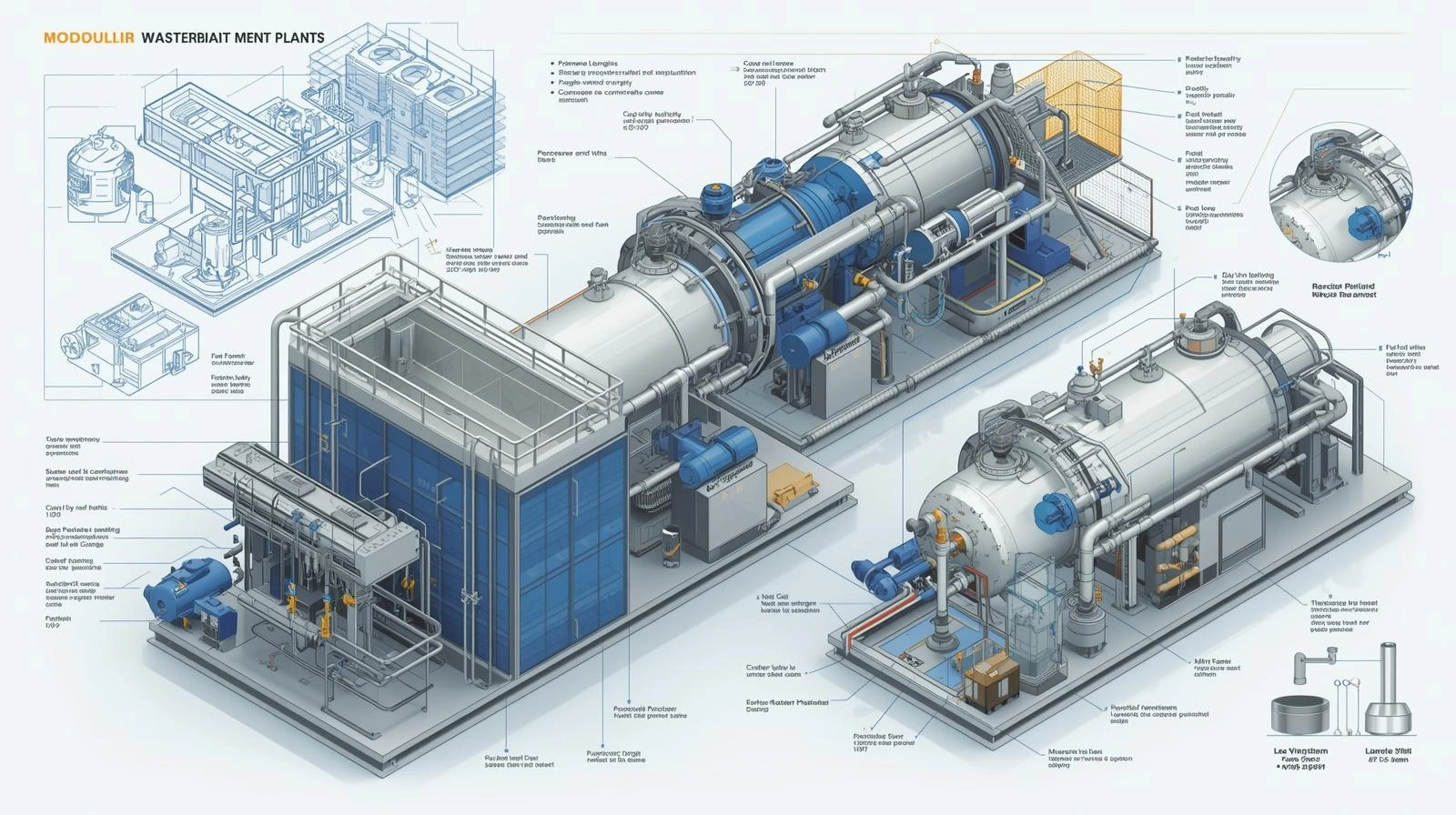

Wastewater Treatment System

What are the design-key elements of a modular wastewater treatment plant for the food processing sector?

1. Flow and load assessment

You must start by quantifying how much wastewater you generate daily and what it contains.

- Measure flow volume (m³/day) for both average and peak times.

- Test for organic load: COD (Chemical Oxygen Demand)/BOD (Biological Oxygen Demand), TSS (Total Suspended Solids), fats, oils & grease (FOG), pH and cleaning-chemical residues.

- Identify variation patterns: e.g., higher loads during washdowns, weekends, product change-overs.

2. Selecting the process train

You’ll typically need a sequence of treatments. For a modular packaged system you might see something like:

- Pretreatment: screening, grit removal, fat/oil skimming.

- Primary biological treatment: MBBR (Moving Bed Biofilm Reactor), MBR (Membrane Bioreactor), or MABR (Membrane Aerated Biofilm Reactor) depending on load. For example, the modular system from Fluence (Aspiral™ Flex) uses MABR to remove BOD, nitrogen and phosphorus in one pass.

- Tertiary treatment and disinfection if reuse is planned: e.g., ultrafiltration/RO, UV, chlorination.

- Sludge management: Dewatering, safe disposal or reuse (e.g., as compost) must be factored.

- Automation & control: Remote monitoring of flows, turbidity, pH, COD for early warning.

3. Modular construction & footprint

Look for containerised or skidded modules (e.g., 20-ft or 40-ft container equivalents) that can be delivered, placed on concrete foundations, connected and commissioned quickly. The module may be pre-wired, pre-plumbed, pre-tested. As per EnviroChemie: “We build complete water technology into one or more modules, exactly as you need it.”

This approach reduces planning/installation time, lowers construction risk, and cuts cost.

4. Compliance and reuse

Since you’re in the food processing sector operating in Pakistan, ensure your system is capable of meeting Pak-EPA and NEQS standards (or any export-related standards if you supply abroad). For example, one beverage-industry case study from Pakistan found high COD and TSS above NEQS levels until treatment was improved.

If water reuse is part of your plan (e.g., rinse water, cooling water), factor in tertiary treatment and make sure module is designed accordingly.

5. Operation & maintenance

Design for simple operation: modular systems often come with SCADA, remote monitoring, alerts and auto dosing. In Pakistan, flexible O&M is important given staffing, utility reliability and resource constraints. For example, local provider Water Care Services Pakistan (WCSP) emphasises modular systems that are “tailored, scalable and sustainable … all systems are optimized for energy efficiency, extended service life and flexibility to fluctuating pollutant loads.”

Example Case

A food-processing facility in Pakistan installs a 50 m³/day packaged modular plant: pre-treatment → MBBR module → UF/RO for reuse in cleaning water. They reported 40% reduction in fresh water purchase, 30% lower discharge cost, and full compliance with NEQS (effluent COD reduced from ~900 mg/L to <70 mg/L).

Expert Insight

“Modular packaged wastewater treatment systems offer the dual advantage of speed and adaptability—especially valuable when your production line or regulatory context changes.”

— Senior wastewater-engineer, global supplier

How do you tailor the modular wastewater treatment system specifically for the food industry in Pakistan?

Why food-industry effluent is special

Food processing plants generate wastewater with variable characteristics: high organic load (from washdown, peeling, blanching), high fats/oils, cleaning chemicals, and sometimes high solids (fruit/vegetable pulp, meat residue). They also face stricter hygiene and regulatory requirements.

Here’s how to tailor your modular system accordingly.

Design considerations

Organics & grease removal

High organics (COD/BOD) and fats require robust biological units. An MBBR or MABR system works well where modules are compact and can be factory-assembled.

For example, the Aspiral™ Flex modular units report >90% removal of total nitrogen and >96% removal of BOD in some configurations.

Install a fat/oil skimming module prior to biological unit to protect downstream process from clogging or upset.

Solids & pulp removal

Trash, peelings and solid organics need screening and settling modules. A modular pre-treatment package should include a fine screen, grit chamber or settling zone.

Variable flow & load

Food plant flows fluctuate. Design the modular system with buffer capacity (equalization tank) to dampen peaks. Modules must tolerate variable loading without performance loss.

Reuse & zero-liquid discharge (if required)

Many Pakistani processors are exploring reuse and ZLD to mitigate water scarcity. The module design should allow for tertiary treatment: UF/RO, UV, or advanced oxidation if necessary. For example, Water Care Services Pakistan emphasises systems that can achieve Zero Liquid Discharge (ZLD) for complex industrial effluents.

Local regulatory & cost-context

Since you’re operating in Pakistan’s food industry wastewater landscape, compliance with NEQS is vital; failure can mean fines or shutdowns. The cost of water (and freshwater scarcity) also makes reuse a strategic advantage. Use local suppliers familiar with Pakistan’s regulations, power supply conditions, and service ecosystem (e.g., WCSP).

Actionable Take-away Checklist

- Measure your water usage and discharge volumes for the last 12 months and map seasonal variation.

- Analyze wastewater composition: BOD, COD, TSS, FOG, pH, chemicals used in cleaning.

- Choose modules sized for the peak rather than average (or include equalization).

- Pick a supplier offering factory-assembled skids/containers, remote automation, and spare-parts support in Pakistan.

- Plan reuse strategy: designate where treated water will go (e.g., non-potable rinse) and specify tertiary module accordingly.

- Negotiate O&M contract from the start (monitoring, preventive maintenance, sludge removal) to avoid downtime.

Mini Case Study

At a mid-sized juice-packaging plant in Haripur (Pakistan) the study “Low Cost Wastewater Treatment at Beverage Industry” found effluent COD and TSS above NEQS until they introduced a combined pre-treatment and biological sequence. They reduced freshwater consumption by ~30% by recycling treated effluent for cleaning operations. That’s a strong proof point for tailoring system design to food-industry needs.

What are the cost, ROI and operational considerations when choosing a modular system?

Capital vs operating costs

Modular systems can lower capital expenditure (CAPEX) by reducing civil construction (less onsite concrete/plumbing) and faster commissioning. For example, EveraTREAT claims 10-35% installed cost savings compared to traditional construction.

Operating expenditure (OPEX) includes energy (a major component) and maintenance. The South Asia lifecycle assessment found energy demand of 0.26-0.64 kWh/m³ for treatment. Lower energy modules (e.g., MABR) can make a big difference.

ROI calculation example

Suppose your plant discharges 100 m³/day of effluent and you pay USD 0.50 per m³ for fresh water plus USD 0.20 per m³ for discharge costs (Kath). Fresh water cost alone ~ USD 50/day = ~ USD 18,250/year.

If a modular plant (including reuse) allows you to cut fresh water usage by 50% and reuse ~40 m³/day, you save ~USD 9,125/year on fresh water plus maybe USD 7,300/year on discharge cost reduction. Total ~USD 16,425 annual savings. If the modular plant costs USD 120,000, payback would be roughly 7-8 years (not counting financing or grants).

Of course, local Pakistani water and disposal rates may differ—but the logic holds.

Additional Factors

- Energy cost & reliability: Pakistan has variable power supply and higher energy cost risk. Select energy-efficient modules and include backup for critical pumps.

- Spare parts & maintenance: Ensure supplier offers local support, spare parts availability and trained staff.

- Sludge disposal cost: A modular plant may produce sludge (or waste solids) you must account for disposal. Some models aim for minimal sludge.

- Future expansion: Choose a modular system that allows adding capacity or modules without complete redesign.

- Regulatory risk: If your effluent fails compliance, you risk fines/shutdown—so design conservative margins into capacity and treatment efficiency.

Pro Tip

Create a total cost of ownership (TCO) model over 10 years: include CAPEX, energy cost escalation (e.g., 5%/yr), maintenance, consumables (chemicals), and compare to “business as usual” costs for fresh water purchase and disposal. Use that to justify investment internally.

How do you select and implement the right modular wastewater treatment provider and project plan for food processing?

Selection criteria

- Food‐industry experience: Ask for reference installations in food processing or beverage sectors.

- Modular design & factory assembly: Prefer providers offering containerised or skid‐mounted modular plants with minimal onsite civil work. E.g., EnviroChemie’s EnviModul series: “complete water technology in one or more modules … reduces planning and installation costs.”

- Technology fit for organics + fats: Ensure the process train handles high COD, FOG, variable flows.

- Compliance credentials: Local supplier should understand Pak-EPA regulations, NEQS requirements, documentation and monitoring. For instance, WCSP emphasizes NEQS compliance in Pakistan.

- Local service and lifecycle support: After-sales service, remote monitoring, preventive maintenance, spare parts must be available locally.

- Flexibility & modular growth path: The supplier should clearly show how modules can scale or be upgraded.

- Cost transparency & ROI model: The vendor should provide CAPEX, OPEX estimates, energy consumption, footprint and payback analysis.

Implementation steps

- Site survey & wastewater audit: Engage vendor to carry out detailed flow measurement and wastewater characterisation.

- Define the specification: Based on loads, decide on capacity (m³/day), target effluent quality, reuse strategy, module configuration, footprint.

- Procurement & contract: Ensure clear scope: supply, delivery, civil works, installation, commissioning, training, warranty, service-level agreement (SLA).

- Construction & installation: Since modules are preassembled, civil works limited to foundations, utilities, pipework.

- Commissioning & monitoring: Run tests for BOD, COD, TSS, FOG removal, ensure compliance with NEQS and any reuse target. Adjust controls.

- Operation & optimisation: Monitor real-time data, adjust load, maintain system. Include operator training.

- Review & scale-up: Monitor usage, maintenance cost and consider adding modules if load increases.

Mini Case Study

A Pakistan‐based supplier (WCSP) offered packaged containerised modular plants for industrial clients including food & beverage. They highlighted: “From tiny industries to giant plants, our modular designs may be sized up or down … optimized for energy efficiency and minimal maintenance.”

The food processor chose a 40 m³/day packaged plant with an equalisation module + MBBR + UV disinfection. After 12 months, discharge COD dropped from ~800 mg/L to <100 mg/L, fresh water consumption dropped 45% and the plant met NEQS limits throughout.

Expert Insight

“Don’t look at the modular plant just as equipment; look at it as a service-contract. The real value is longevity, performance, compliance and water reuse—not just CAPEX.”

— Consultant, industrial water treatment

What are the trends and future outlook for modular wastewater treatment in food processing (2024-2025)?

Trends to watch

- Increased adoption in developing markets: As Pakistan and other South Asian countries face water scarcity, stricter regulations and ESG pressures, modular packaged wastewater plants are becoming more attractive.

- Smart monitoring & IoT integration: Vendors are embedding sensors, remote monitoring and predictive maintenance into modules. For example WCSP mentions SCADA/IoT integration.

- Energy-efficient biological technologies: MABR systems like those in the Aspiral™ Flex product reduce energy consumption significantly.

- Water reuse and circular economy: Food processing plants increasingly adopt reuse of treated water for cleaning, cooling, blanching to reduce fresh water intake and discharge.

- Pre-fabricated modules and containerised systems: Rapid deployment, minimal civil works, and ease of relocation or expansion.

- Lifecycle & sustainability assessments: More emphasis on full lifecycle costs and environmental impact (including GHGs, electricity use, chemical use). For instance, a recent South Asia study emphasised energy/chemical consumption as key impacts in treatment systems.

Outlook for Pakistan’s food sector

In Pakistan’s food processing industry wastewater context, you’ll likely see:

- More regulatory enforcement of NEQS and discharge quality in industrial corridors.

- Greater scrutiny of large-food-processing plants for water reuse and pollution control.

- Modular packaged plants becoming the default for new food plants rather than traditional built‐onsite ETPs.

- Opportunities for integrated solutions: combining wastewater treatment with water reuse modules, automation and O&M service contracts.

Actionable Insight for You

If you are operating (or advising) a food processing unit in Pakistan, now is the time to pilot a modular packaged wastewater plant. Set up a small-scale version (e.g., 20-40 m³/day) to test the system, monitor performance, then roll out larger capacity. Build in instrumentation (flow meters, sensors) upfront so you can track benefits and build a business case for expansion.

Conclusion

Designing a modular wastewater treatment plant for the food processing industry—especially in Pakistan’s context—offers a powerful way to solve significant pain points: managing high-organic and variable flows, complying with NEQS for industrial wastewater, reducing fresh water purchases and disposal costs, and scaling your operations sustainably.

We covered why modular systems matter for the food industry, the key design elements you must evaluate, how to tailor the system for food-industry effluent in Pakistan, how to select a provider and implement successfully, plus the 2024-2025 trends pushing the field forward.

Now it’s over to you: take the flow audit, test your wastewater, run the ROI model, and engage with a modular supplier. Don’t wait until compliance or water cost pressures force your hand. Invest smartly and act now.

If you’d like a ready-to-use checklist, vendor evaluation template or cost-model spreadsheet, I’m happy to help. Let’s build your water-smart, cost-efficient future together.

FAQ

1. What exactly is a modular wastewater treatment plant?

A modular wastewater treatment plant is a factory-assembled or containerised unit where key treatment components (screens, biological reactor, clarifier, disinfection) are pre-integrated, delivered to site, connected quickly and operational in far less time than a traditional build. For example, the Aspiral™ Flex system by Fluence offers containerised modules that cover 20-950 m³/day flows.

2. Why is modular wastewater treatment especially relevant for the food industry in Pakistan?

Food processing in Pakistan generates effluent with high COD/BOD, fats/oils, solids, variable flows and water scarcity issues. Modular plants cater to these challenges by offering compact, efficient, scalable systems that enable reuse and compliance with NEQS. The local industry is already adopting packaged solutions.

3. What typical effluent parameters should I expect for a food-processing plant?

Typical parameters might include:

- COD: often 500-1,500 mg/L or higher before treatment (depends on processing type)

- BOD: ~200-800 mg/L

- TSS: several tens to hundreds mg/L

- FOG (fats/oils/grease): significant if washdown of food oils occurs

- pH: may vary depending on cleaning chemicals

You’ll need an effluent audit to know your specifics and design accordingly.

4. How much does a modular packaged plant cost and what is the payback period?

Costs vary widely (capacity, technology, reuse level, local labour). As a ballpark: if a plant treats 100 m³/day and saves you USD 16k/year (via water savings and disposal reduction) and costs USD 120k, payback ~7-8 years. Your actual payback depends on water/discharge costs in your region, energy costs, and load reduction benefits.

5. Can I expand a modular system if my production grows?

Yes. One of the key advantages of modular is scalability. You can add “modules” or parallel units, or upgrade modules (e.g., adding tertiary treatment) as production increases. Make sure your supplier offers clear expansion paths.

6. Are these modular systems reliable in Pakistan’s context (power outages, maintenance constraints)?

They can be reliable if properly designed. Choose vendors with local support, modules rated for local power fluctuations, include automation and alerts, and plan for preventive maintenance. Also build in backup power or downtime contingency.

7. What are common mistakes when implementing modular wastewater plants in food processing?

- Undersizing the unit based on average flow instead of peak load.

- Ignoring fats/oil content which can block downstream modules.

- Neglecting sludge handling and disposal costs.

- Overlooking reuse potential and designing only for discharge.

Not planning for local service, spare parts, and operator training.

Avoiding these mistakes will dramatically improve your outcomes.