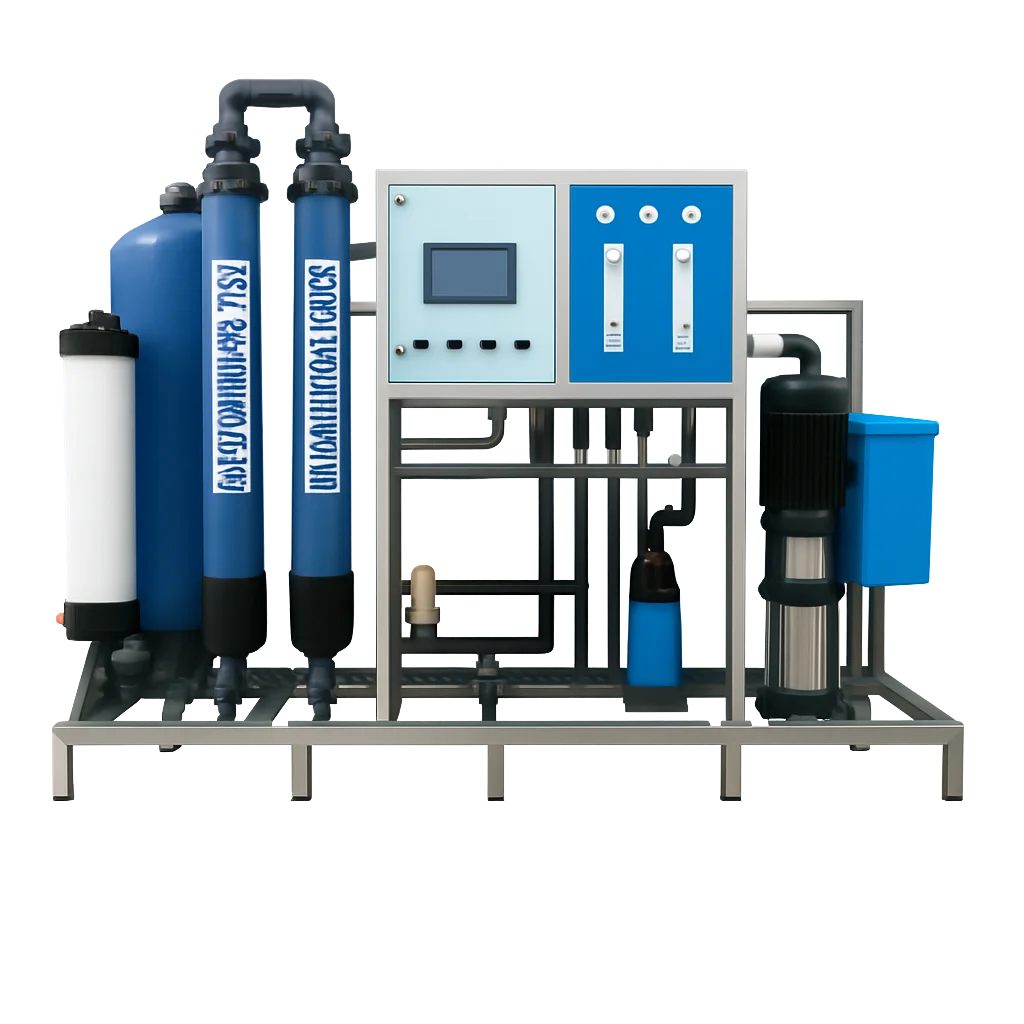

Demineralization Water System

Demineralization (DM) Water System – High Purity Water for Industrial Applications

Demineralization is a reliable and efficient technique for producing ultra-pure water by eliminating dissolved salts and minerals. Using cation and anion exchange resins, this process generates deionized water with exceptionally low conductivity. For industries requiring highly pure water, DM plants can be combined with Reverse Osmosis (RO) systems or advanced Electrodeionization (EDI) units to provide continuous, chemical-free water purification, ensuring consistent quality for critical applications.

Water Care Services Pakistan is a leading supplier of compact and industrial Demineralization (DM) Water Plants, widely used in laboratories, pharmaceuticals, and power industries across Pakistan.

Complete Water Treatment Solutions

Discover our full range of advanced purification technologies:

Demineralization (DM) Water Plants

Distilled Water Plants

Water Softening Units

Each system is designed for high efficiency, reliability, and long service life, meeting the unique needs of different industries.

Salient Features

Demineralization (DM) Water Plants

Produces water with conductivity below 1 µS/cm

Available in two-bed and mixed-bed configurations

Easy to install and user-friendly operation

Fully automatic regeneration with acid/alkali

Skid-mounted and compact design

Long-lasting ion exchange resins

Why Demineralization (DM) Water System?

Most impurities in raw water are dissolved salts. Demineralization technology ensures these are removed, producing water as pure as distilled water but faster and more cost-effective.

✅ Prevents scale formation in boilers and turbines

✅ Ensures consistency in pharmaceutical and cosmetic formulations

✅ Provides safe, high-purity water for laboratories and hospitals

✅ Meets the water quality standards for industrial production

How It Works

Our DM Plant uses advanced ion exchange resins:

Cation Exchange Resin – removes positively charged ions (Ca²⁺, Mg²⁺, Na⁺, etc.)

Anion Exchange Resin – removes negatively charged ions (Cl⁻, SO₄²⁻, NO₃⁻, etc.)

When water passes through these resins, the dissolved salts are replaced with hydrogen and hydroxyl ions, producing pure demineralized water. Once the resins are saturated, they are regenerated using acids and alkalis.

For higher purity, a mixed-bed unit or EDI technology is used to polish the water to below 1 microsiemens.

Why Demineralization Matters:

In industries where water quality is paramount, such as power plants, pharmaceuticals, electronics, laboratories, and hospitals, the need for pure and de-ionized water is critical. Our Demineralization Water Systems are designed to remove minerals, salts, and impurities, ensuring a reliable source of high-purity water for your specific applications.

State-of-the-Art Technology:

At Water Care Services, we leverage advanced technology, including ion exchange and membrane filtration methods, to tailor solutions that meet the unique requirements of each client. Whether you're looking for a two-bed deionization system or a mixed-bed configuration, our expertise ensures optimal performance and water quality.

Comprehensive Industry Solutions:

Our services cater to a diverse range of industries, addressing the water treatment needs of power plants to prevent scale formation, providing high-purity water for pharmaceutical manufacturing, supporting electronic component production, and meeting the stringent standards of laboratories and hospitals.

Get Reliable, Cost-Effective Water Solutions for Your Industry

Why Choose Water Care Services?

At Water Care Services, we take pride in offering cutting-edge solutions for your water treatment needs. As a leading provider in the industry, our commitment is to deliver unparalleled expertise and top-notch services, with a primary focus on Demineralization Water Systems.

Expertise That Matters:

With years of experience in the water treatment industry, Water Care Services stands as a beacon of expertise. Our team of skilled professionals is dedicated to understanding your unique requirements and providing customized solutions that exceed expectations.

Reliable Maintenance and Support:

We understand the importance of consistent water quality. That’s why we offer comprehensive maintenance services, including resin regeneration and membrane replacement, ensuring the longevity and effectiveness of your Demineralization Water System.

Client-Centric Approach:

At Water Care Services, client satisfaction is at the heart of what we do. Our client-centric approach means you can trust us to deliver not just water treatment solutions, but peace of mind.

Contact Water Care Services Today

Ready to elevate your water treatment strategy? Contact Water Care Services today for unparalleled Demineralization Water System solutions. Let us be your trusted partner in ensuring a reliable and pure water supply for your industrial and commercial needs.

A Demineralization Water System is designed to remove mineral ions, such as calcium and magnesium, from water through ion exchange processes, ensuring a more purified water supply.

Demineralization is crucial in industrial settings to prevent scale formation, corrosion, and interference with processes that require high-purity water, such as boiler feedwater in power plants.

While water softening primarily focuses on reducing hardness by removing calcium and magnesium, demineralization goes a step further by eliminating a broader range of mineral ions, ensuring high-purity water.

Demineralization methods include ion exchange, reverse osmosis, and distillation. Each method has its advantages and limitations, and the choice depends on specific water quality requirements.

Demineralization systems are highly effective in removing mineral ions, but additional treatment processes may be required to address other impurities, depending on the water source and quality.

Industries such as power generation, pharmaceuticals, electronics manufacturing, and boiler feedwater applications extensively use demineralization systems to ensure high-quality water for their processes.

The frequency of resin regeneration depends on the water quality and usage. Regeneration involves passing a concentrated solution of regenerant through the resin bed to replace adsorbed ions.

Demineralization is typically more suitable for industrial applications due to its complexity and the need for precise water quality control. Water softeners are more common in residential settings.

Demineralized water can be corrosive, so additional measures such as pH adjustment and corrosion inhibitors may be necessary in certain applications to maintain system integrity.

Regular monitoring of water quality, resin condition, and system performance is essential. Scheduled maintenance, including resin regeneration and equipment checks, ensures the continued effectiveness of the demineralization system.